5 Band Resistor Color Code

Resistor tolerance—now there’s a term that dances on the edge of precision! It reveals just how closely a resistor’s actual value aligns with its claimed resistance, and it does so in the form of a percentage. This percentage isn’t just window dressing; it embodies the allowable wiggle room in resistance when subjected to specific conditions. You’ll often encounter common tolerances like ±1%, ±5%, and ±10%. Interestingly, those snugger tolerances tend to cozy up with high-precision applications, where every fraction counts. Grasping this concept is pivotal, particularly in circuits where accuracy reigns supreme. A seemingly minor variation can ripple through circuit performance, affecting everything from signal integrity to temperature sensitivity.

Now let’s pivot to temperature coefficients! These clever little indicators shed light on how a resistor’s value morphs as temperatures rise or fall. Expressed in parts per million per degree Celsius (ppm/°C), they serve as crystal balls for predicting behavior in fluctuating thermal landscapes. Resistors boasting low temperature coefficients are like golden tickets for scenarios demanding stability amidst thermal upheavals. For designers aiming for reliable performance across an array of operating conditions, having an astute understanding of both tolerance and temperature coefficients isn’t just beneficial—it’s essential!

Understanding Resistor Tolerance

Ah, resistor tolerance—what a fascinating concept! It represents the wiggle room in resistance values that a resistor can flaunt under standardized conditions. This factor is not just a minor detail; it plays a pivotal role in how closely the actual resistance of your trusty resistor matches its nominal value. You might encounter typical tolerance ratings like ±5%, ±1%, and even an impressively precise ±0.1%. The lower those tolerance figures are, the higher the precision we’re talking about! Picture this: a 1% tolerance resistor strutting its stuff in sensitive circuits delivers performance with pinpoint accuracy, far surpassing what you’d get from one with a 5% rating. Thus, choosing the right level of tolerance becomes crucial for particular applications.

For engineers, grasping this concept goes beyond mere curiosity—it’s essential since it directly influences circuit performance and stability. When you step into high-precision realms like medical devices or aerospace technology, tight tolerances become non-negotiable to guarantee safety and reliable operation. On the flip side, less critical applications may be perfectly happy with broader tolerances without breaking a sweat. So understanding all these nuances around resistor tolerance isn’t just academic; it’s about optimizing designs and boosting overall circuit reliability! Focusing on these little details ultimately paves the way for achieving that desired electrical performance across diverse scenarios—and oh, what intricate webs we weave when crafting our circuits!

| Tolerance Rating | Typical Applications | Advantages |

|---|---|---|

| ±0.1% | Precision instruments, medical devices | High accuracy and reliability |

| ±1% | Audio equipment, high-end electronics | Balanced performance and cost |

| ±5% | General purpose, consumer electronics | Cost-effective and widely available |

| ±10% | Low-end consumer products, DIY projects | Very affordable option |

Applications of 5 Band Resistors

In the intricate world of electronics, 5 band resistors emerge as heroes where precision reigns supreme. Picture high-frequency circuits—those fast-paced realms where stability must dance gracefully across a spectrum of conditions. These resistors don’t merely provide resistance; they deliver an exquisitely fine-tuned value with astonishingly narrow tolerances. This makes them indispensable in demanding devices like cutting-edge medical apparatus, sophisticated instrumentation, and the ever-evolving landscape of telecommunication systems.

But wait! Their talents extend beyond specialized electronics—they venture boldly into the automotive and aerospace arenas as well. Here, their durability and reliability shine bright amidst environments that thrash against significant strain and unpredictable conditions. It’s this very versatility that allows engineers to weave these components into complex systems—a tapestry requiring not just accurate resistance values but also unwavering long-term stability under a kaleidoscope of operational stresses.

Where 5 Band Resistors Are Used

Ah, the 5 band resistors! These little wonders are not just mere components; they’re the unsung heroes of precision engineering, weaving their magic in realms where resistance values must be meticulously controlled. A beacon of accuracy, they shine brightly in instrumentation and high-precision circuits—places where every milli-ohm counts. Picture this: telecommunications and audio equipment flourishing thanks to these resistors, ensuring that signal integrity reigns supreme amidst a sea of electronic chaos.

But wait! Their prowess doesn’t stop there. Dive into the world of medical devices, and you’ll find them lurking within critical systems—where reliability isn’t just a bonus; it’s a matter of patient safety.

And let’s not overlook another fascinating domain—the intricate dance of automotive electronics! Here, 5 band resistors strut their stuff under stringent performance standards. They orchestrate the symphony between various sensors and control modules in vehicles with finesse.

Oh yes, even consumer electronics can’t escape their grasp! In smartphones and computers alike, these versatile champions ensure optimal functionality across an ever-evolving technological landscape. With such remarkable adaptability and unwavering reliability at play, engineers are empowered to craft increasingly sophisticated circuits that stand as testaments to innovation across numerous fields.

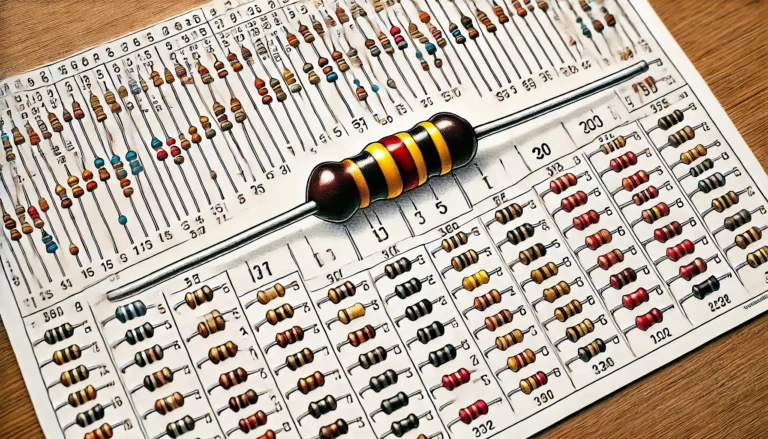

Common Mistakes in Reading Color Codes

Misunderstanding the color bands on resistors? Oh, it’s a commonplace blunder that ensnares many in the electronics realm! Picture this: individuals squinting under dim lighting, grappling with hues that dance between red and brown—it’s an easy trap to fall into, especially when those colors start to fade. But wait! There’s more; let’s not forget about the order of those bands. A simple mix-up can spiral into chaos, throwing circuit designs and functionality completely off-kilter.

And then we have the infamous tolerance band—the often-ignored hero of resistor readings. Users become so laser-focused on deciphering those initial bands that represent resistance value that they unwittingly bypass this critical piece of information. This oversight? It could spell disaster for precision-dependent applications where even a slight deviation might unravel the very fabric of an electronic project’s integrity!

Errors to Watch Out For

Ah, the intricate dance of deciphering resistor color codes! One prevalent pitfall that many stumble into involves a misinterpretation of those vibrant hues, often thwarted by poor lighting or an annoying glare. It’s crucial that each shade stands out boldly to prevent any muddled conclusions—after all, when similar colors mingle under subpar conditions, it can spiral into significant miscalculations. Consider this: in certain lights, the subtle variance between brown and red could become nearly indistinguishable, leading one down a treacherous path of erroneous value assignment. Thus, ensuring your workspace is bathed in proper lighting and visual clarity isn’t just helpful; it’s essential for achieving accuracy.

Yet another common blunder arises from the physical state of the resistor itself. Damage—be it fading colors, corrosion’s creeping grip, or unwelcome dust—can severely hinder visibility of those critical color bands. When faced with such deterioration, determining the true value becomes a formidable task indeed! Regularly cleaning components and inspecting them for wear can dramatically diminish these chances for error. By cultivating familiarity with these typical traps, one empowers themselves to wield resistors with greater reliability and precision—a veritable mastery over electrical enigmas!

Tools for Resistor Measurement

The precise measurement of resistors stands as a cornerstone for optimal circuit performance, an undeniable truth in the realm of electronics. Enter the multimeter—this multifaceted and omnipresent tool that elegantly straddles the line between resistance testing and continuity checks. With both analog and digital versions gracing our workbenches, each brings its own unique flair to the table. Digital multimeters leap ahead with their uncanny precision and effortless readability, while analog counterparts still hold court in certain niches, prized for their instantaneous reaction to fluctuating values—a dance of numbers on a dial.

But wait! There’s more. Clamp meters wade into this arena too, proving invaluable when it comes to measuring current within those expansive circuit setups. They offer a clever workaround: assessing resistance without intruding upon the flow—their jaws wide open yet non-invasive.

Beyond these staples lie specialized instruments like LCR meters, which don’t just stop at resistance; they venture into inductance and capacitance territory too—painting a rich tapestry of component behavior that is anything but one-dimensional. For those venturing into advanced applications? Precision resistor decade boxes come into play—allowing users to simulate resistance values with surgical accuracy! This nifty capability proves indispensable for testing and calibrating circuits—all without juggling multiple individual resistors like some electronic circus act.

Navigating through this landscape requires an intimate understanding of what each tool can do—a mastery essential for effective resistor measurement—and undeniably pivotal in crafting reliable electronic designs that sing harmoniously together in their intricate dance of electricity.

Essential Equipment for Accurate Readings

In the intricate dance of electronics, where precision is paramount, the accurate measurement of resistor values hinges on specialized equipment crafted for this very purpose. Enter the digital multimeter—a quintessential tool in this realm. This device empowers users to gauge resistance with remarkable accuracy, spitting out readings in ohms that are as clear as day. But wait—there’s more! The advanced models strut their stuff by offering nifty extras like capacitance measurement and frequency analysis, transforming them into Swiss Army knives for an array of electronic testing scenarios.

Then we have the precision resistor decade box—another heavyweight champion in our toolkit. This ingenious contraption allows you to dial up resistance values with astonishing exactitude, simulating various levels within a circuit without the hassle of juggling multiple physical resistors. When these tools join forces, they create a symphony of reliable measurements that both seasoned electronics pros and enthusiastic hobbyists can revel in, paving the way for superior circuit design and stellar performance outcomes.

- Digital multimeter provides versatile measurement capabilities.

- Offers high accuracy for resistance readings.

- Advanced models include additional features like capacitance and frequency measurement.

- Precision resistor decade box enables customizable resistance values.

- Facilitates circuit testing without the need for multiple resistors.

- Enhances reliability in electronic component evaluation.

- Essential for both professional engineers and hobbyists.

Maintaining Resistor Performance

Resistors—those unsung heroes of electronic circuits—are absolutely vital, and ensuring their performance remains steadfast over the years is no small task. Regular inspections and testing stand as guardians against potential issues lurking in the shadows, like sneaky temperature fluctuations or unwarranted voltage spikes. Keeping a watchful eye on operational conditions is not just prudent; it’s essential! Environmental factors such as humidity and temperature can wreak havoc on resistor functionality, turning reliable components into ticking time bombs.

Proper storage isn’t merely an afterthought; it’s a cornerstone for longevity, shielding resistors from the relentless assault of external elements that threaten degradation. To bolster reliability, one must prioritize quality components—a non-negotiable in this intricate dance of electronics. Choosing resistors with suitable ratings tailored to their intended applications significantly diminishes failure risks.

And let’s not overlook the art of soldering! Maintaining optimal temperatures during this process is crucial to prevent catastrophic damage to these critical parts. Adopting sound circuit design principles and layout practices acts like a safety net, easing stress on resistors and ultimately extending their operational lifespan far beyond initial expectations. In essence, every detail matters when safeguarding these pivotal players in our technological symphony!

Tips for Ensuring Long-Term Stability

The meticulous handling and storage of 5 band resistors can play a pivotal role in their enduring stability. Imagine, if you will, these tiny warriors of resistance nestled in a cool, arid haven—far from the clutches of excessive humidity and wild temperature swings. The gold standard here? Anti-static bags are your allies, while corrosive materials lurk as enemies to be avoided at all costs to stave off degradation. A routine inspection is not just advisable; it’s essential! Spotting even the faintest signs of wear or damage early on enables you to take proactive steps before performance takes a nosedive.

But wait—there’s more! Implementing regular testing intervals isn’t merely beneficial; it’s downright crucial for ensuring that these little giants continue to function within their specified tolerances. Armed with calibrated measurement tools, one can glean accurate readings that unveil the true state of these resistors. And let us not overlook the environment in which they operate; this consideration becomes key in selecting resistors endowed with suitable temperature coefficients and tolerances. This anticipatory strategy doesn’t just boost reliability—it stretches out the lifespan of components across a myriad of electrical applications like taffy pulled at both ends!

Conclusion

Delving into the labyrinthine world of the 5 band resistor color code unveils a treasure trove of insights, captivating both fledgling hobbyists and seasoned electronics aficionados alike. The myriad benefits these resistors offer—think enhanced precision and unwavering reliability across a spectrum of applications—cement their status as go-to components in intricate circuitry designs. As technology races forward, the clamor for precise resistance values intensifies, underscoring why mastering this colorful coding system is nothing short of essential.

A solid education in deciphering and applying resistor values can dramatically elevate performance levels in electronic undertakings. Being mindful of frequent pitfalls while wielding the right measurement tools can ensure that circuit designs stand on firm ground. This knowledge not only acts as a safeguard against errors but also plays a pivotal role in fostering efficient operation and extending the lifespan of our cherished electronic gadgets.