The History of Resistor Color Coding

Table Of Contents

The History of Resistor Color Coding and Its Impact on Resistor Color Codes and Colour Code Standards

Key Takeaways

- The development of resistor hue identification and its transformation over time

- Grasping the meaning behind resistor color markers

- The importance of resistor shades in electronics

- Differences in resistor color identification systems

- Real-world uses of resistor color indicators

The History Of Resistor Color Coding | The Evolution of Resistor Color Coding

The History of Resistor Color Coding reveals a fascinating progression from early identification methods to standardized systems. Initially, resistors were often labeled manually with values or markings that varied widely among manufacturers. This inconsistency sparked the need for a more uniform approach. The introduction of the resistor color codes represented a pivotal shift, utilizing a series of colored bands to communicate resistance values efficiently. The implementation of the RMA resistor color code, alongside other resistance colour codes, allowed for easier reading and understanding of the resistor values. Over time, the proliferation of different resistor colors and their meanings has established a global standard, making the identification of fixed resistor values accessible to engineers and hobbyists alike. This evolution has ensured that the resistor code remains a crucial aspect of electronic design, fostering consistency and clarity across various applications.

The History of Resistor Color Coding | Early Methods of Identifying Resistors

Early methods of identifying resistors relied on various marking codes that varied by manufacturer. Before the standardization brought by The History of Resistor Color Coding, resistivity values were often indicated using alphanumeric characters or simple symbols that could be confusing. This lack of consistency made it difficult for engineers to accurately interpret the specifications of fixed resistors and wire resistors. Some manufacturers even used hexadecimal color codes or other unique systems, resulting in a landscape filled with ambiguity. The introduction of standardized electronic color codes aimed to alleviate these issues.

The electronic colour code system gained popularity due to its simplicity and efficiency. This system employed bands of color to represent the resistance value, tolerance, and reliability of the components, including film resistors and zero-ohm resistors. The ANSI color codes and RMA color coded standards ensured a more uniform method for identifying resistor values, making it easier for both designers and manufacturers. As the electronic industry evolved, these standardized color codes became essential for distinguishing between different types of resistors, including marking codes for resistors and capacitors.

The Introduction of Resistor Colour Codes

The History of Resistor Color Coding showcases the transition from early identification methods to a standardized system based on colors. The introduction of the 25-pair color code paved the way for easier recognition of different electrical resistances. By using a color palette, engineers and technicians could identify resistors quickly and accurately. This innovation simplified the manufacturing and usage of components like pull down resistors and wire-wound resistors, which are essential in various electronic applications.

The establishment of the EIA color code and ANSI color standards further solidified the importance of color in understanding resistor values. Each color corresponds to a specific digit or multiplier, providing a clear visual representation of a resistor’s resistance. The integration of color models, including the RGB color model, has expanded the application of these codes across different disciplines. This structured approach has not only enhanced clarity for resistors but also for capacitors, ensuring that engineers can navigate complex circuitry with confidence.

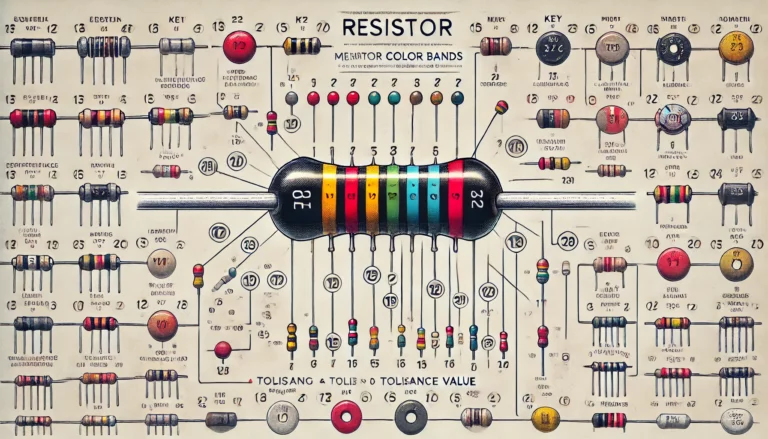

Understanding Resistor Color Codes

Resistor color codes play a crucial role in electronics, allowing for quick identification of resistance values and specifications on circuit boards. The history of resistor color coding dates back to the mid-twentieth century when these codes were first introduced, establishing a standardized method for indicating resistance. Each color corresponds to a number, creating a system that can even accommodate color-blind individuals through specific hex color combinations. Understanding this system is essential not only for compliance with the Canadian electrical code but also for grasping the temperature coefficient of resistance, which influences how resistors behave under different conditions. The development of color-coded resistors has significantly enhanced the efficiency of electrical design and maintenance, reflecting the importance of the history of resistor color coding in modern electronics.

- Resistor color codes use a series of colored bands to indicate resistance values.

- Each color corresponds to a numerical value, typically ranging from 0 to 9.

- The first two bands represent significant digits while the third band indicates the multiplier.

- The fourth band, if present, signifies tolerance, indicating how much the resistor’s value can vary.

- Specialized color codes exist for identifying temperature coefficients and reliability.

- Understanding resistor color codes improves troubleshooting and maintenance in electronic circuits.

- Familiarity with this coding system is vital for both beginners and advanced electronic enthusiasts.

The Basics of Resistor Color Code Interpretation

Understanding resistor color code interpretation is fundamental for anyone working with electronics. The History of Resistor Color Coding reveals how resistor body colors and the method of using colored bands have evolved over time. Each of the resistor color bands represents a numerical value, allowing individuals to quickly identify a resistor’s resistive value. This system is especially useful for tracing resistor-like components in various applications, ensuring that one selects the right resistor for the desired electrical function.

Resistor values can vary significantly based on design and intended use. New resistor technologies have introduced flexible resistor color options, alongside traditional options like antique resistor color and rma resistor color. A multi-purpose resistor code uses colored bands effectively, making it easier for technicians to determine basic resistor values at a glance. Knowing these interpretations saves time and reduces errors when integrating resistors into electronic circuits, leading to more efficient designs.

Common Resistor Color Combinations

Resistor color codes have evolved significantly, reflecting The History of Resistor Color Coding. Many resistors, including old style resistors, utilize a color coding system that simplifies the understanding of resistance values. Typically, a resistor package will feature multiple colored bands that represent the resistor’s value and tolerance. Popular resistor kits often include these color-coded components, allowing users to easily read resistors and select the appropriate values for various electronic projects.

Several combinations of colors indicate specific values and tolerances, crucial for achieving the desired performance in circuits. Specialized resistors, such as fusible resistor types, may also follow this color coding to maintain consistency across different applications. Understanding these color codes plays a significant role in resistor technology. Knowing how to interpret the tolerance color alongside resistance value allows individuals to create their own resistors with precise specifications, ensuring optimal functionality in electronic devices.

The Significance of Resistor Colour

The significance of resistor color coding lies in its ability to convey critical information about resistive values and tolerance in a compact format. The history of resistor color coding reveals developments that led to the establishment of standard color codes, such as the RMA resistor code, which simplifies the identification process for both manufacturers and hobbyists alike. For example, a band resistor may display multiple colored bands, each representing different digits and multipliers, forming a reliable resistor identification system. This color-coded approach not only aids in selecting the correct ohm resistors but also helps in understanding how resistor derating affects circuit performance. Homebrew resistors often utilize similar principles, emphasizing the importance of accurate color code interpretation. Understanding the color code backwards can also be beneficial for troubleshooting, ensuring that users can quickly assess component functionality and integrity.

| Color | Digit/Tolerance | Multiplier |

|---|---|---|

| Black | 0 | 1 |

| Brown | 1 | 10 |

| Red | 2 | 100 |

| Orange | 3 | 1,000 |

| Yellow | 4 | 10,000 |

| Green | 5 | 100,000 |

| Blue | 6 | 1,000,000 |

| Gold | Tolerance: ±5% | N/A |

| Silver | Tolerance: ±10% | N/A |

How Resistor Colour Affects Functionality

Resistor color coding plays a crucial role in determining the functionality of various resistor types, including ordinary type resistors and precision resistors. The History of Resistor Color Coding highlights how early engineers developed systems to identify resistance values accurately. The standard color code allows for the identification of resistance in four-band resistors, three-band resistors, and even more complex six-band resistors. High precision resistors, like the red five-band resistor, utilize additional bands to indicate tighter tolerances, making them essential in circuits requiring precise measurements.

The impact of resistor color coding extends to modern tools like the automatic resistor calculator and online resistor calculators. These tools facilitate the quick interpretation of resistor values and assist engineers with their designs. SMD resistors often adopt the same color coding principles, ensuring consistency across different resistor forms. As technology advances, understanding resistor functionality through color coding remains vital for both hobbyists and professionals working with various electronic components.

The Impact of Standardization on Resistor Codes

Standardization in resistor color codes has played a crucial role in simplifying the identification of resistor values across various applications. The History of Resistor Color Coding showcases the evolution from early identification methods to the adoption of standardized systems. This transition facilitates easy recognition of characteristics through consistent colour codes. For instance, four-band resistors and five-band resistors employ the same color code principles, making it intuitive for engineers and hobbyists alike to interpret colour code values. High-voltage resistors often adhere to these established standards, ensuring that users can safely manage higher power levels without confusion.

Embracing ANSI color codes and hex color codes helped create a uniform understanding among manufacturers and users in the electronics industry. These standards outline specific color boundaries and definitions, which means that exceptions to the color code are less frequent, reducing the chances of misinterpretation. As a result, it enhances the reliability of components, especially when dealing with high voltage resistors. The significance of this standardization cannot be understated. With a common framework for color coding, individuals can easily access vital information about a resistor’s specifications, optimizing use in a variety of electronic devices.

Variations in Resistor Color Coding

The History of Resistor Color Coding reveals a fascinating evolution in how resistors are identified and categorized. Different color schemes have emerged, such as the widely adopted band color code for cylindrical composition resistors and surface mount resistors. These methods utilize a consistent color scheme where adjacent colors correspond to numerical values, aiding in the easy interpretation of a resistor’s resistance. The introduction of hex color code has enhanced precision for specific applications like ohmic and high voltage resistors, making identification more straightforward. The first color in the sequence often sets the tone for the entire code, while the neutral background color provides clarity against which the colors can be easily distinguished. Color code charts play a crucial role in this process, allowing users to decode the meanings behind different color combinations effectively.

Comparing Different Resistor Colour Schemes

Different resistor color schemes have evolved over time, influenced by The History of Resistor Color Coding. Common color choices include brown, red, and orange, which correspond to specific resistance values. The use of tolerance codes adds another layer, indicating how much the actual resistance value may vary from the marked value. This variance is crucial, especially in applications requiring low resistance, as even minor resistance value changes can significantly impact circuit performance.

Color formats can differ based on regions and manufacturer standards, leading to confusion among electronics enthusiasts and professionals alike. Some schemes utilize four bands while others employ five, creating a spectrum of color values that must be correctly interpreted to achieve the same resistance. Understanding these variations in colors and their meanings is essential for accurate assembly and troubleshooting of electronic devices.

Global Differences in Resistor Codes

The History of Resistor Color Coding reveals a fascinating journey through time as different regions adopted various color coding schemes. Precise color matching became essential to ensure clarity in identifying resistance values. While many places use the standard four-band color codes, some have incorporated five-band and six-band color codes for more specific measurements. Differences in color bands across borders can lead to confusion. This is particularly true when different colors represent varying resistance values or tolerances, as the second color in the sequence can change the interpretation significantly.

Different countries may also implement additional colors to enhance their coding systems. Specific colors might stand for tolerances or temperature coefficients, which can vary from the typical color sequence. The limited color palette associated with resistors sometimes results in low brightness colors being used simply to distinguish values. Understanding these global differences in resistor codes is crucial for anyone working with electronic components, as it can prevent misinterpretation and ensure accurate assembly or repairs based on The History of Resistor Color Coding.

Practical Applications of Resistor Colour Coding

Resistor color coding plays a crucial role in the practical applications of electronics, stemming from The History of Resistor Color Coding. Understanding the color order and the significance of different colours allows engineers and hobbyists to quickly interpret marking codes, facilitating consistent color experiences across devices. Unique color combinations convey varying levels of resistance, where specific colors can indicate little resistance or higher values. The use of bright colors and the inclusion of the fourth color, often gold, helps in distinguishing tolerances, vital for ensuring circuits function correctly. As resistance generates heat, knowing how colors matter in resistor identification can prevent malfunctions and contribute to overall circuit reliability, reinforcing the value of adhering to established rma color standards.

- Understanding resistor color coding aids in accurate circuit design and troubleshooting.

- Quick identification of resistors helps in efficient repairs and modifications.

- Engineers can ensure proper component selection based on tolerance and resistance values.

- Color coding reduces the risk of errors when assembling or disassembling electronic devices.

- Facilitates communication among technicians and engineers by providing a standardized reference system.

- Enhances learning for electronics students by simplifying the concept of resistance values.

- Promotes efficiency in manufacturing processes by speeding up quality control assessments.

Resistors Colour Coded in Everyday Electronics

The History of Resistor Color Coding has greatly influenced the way resistors are utilized in everyday electronics. Most commonly, resistors feature coloured bands, each representing a specific numerical value according to the established color chart. The combination of these bands creates a coding system that allows for quick identification of a resistor’s preferred resistance. The standard 4-band system is widely used, but variations like the 5-band color system introduce an extra color band for greater precision. The inclusion of a third color allows for finer resistance ranges, which is essential for modern electronic applications.

Printed-circuit boards are laden with resistors that employ these color codes to ensure efficient functionality and design. The body color and ring color of each resistor can vary—blue is often used for a specific resistance value, while non-standardised jacket colors may indicate unique characteristics or specifications. Understanding the different codes and their meanings helps engineers and hobbyists accurately work with components, ensuring the right resistors are used in circuits. As technology advances, the principles laid out in The History of Resistor Color Coding remain integral to the design process in electronics.

Conclusion

The History of Resistor Color Coding reveals the intricate system developed to identify resistor values through a series of body colors, each representing a specific number. This method allows for quick interpretation of many circuits, where a simple glance can provide essential information. The use of dot color on certain resistors further aids in distinguishing variations like tolerance and temperature coefficient. Understanding these elements enhances the efficiency and accuracy of electronic design, ensuring that components function correctly within their intended applications. The consistent application of these color codes emphasizes the significant advancement in electronic engineering and design practices over time.

FAQS

How does the resistor colour code facilitate the identification of a resistor and its characteristics, particularly for those who are color blind?

The resistor colour code is a critical system that uses colored bands to quickly identify a resistor’s resistive value. These resistor colour codes were first introduced in the mid-twentieth century and provide a consistent color scheme with corresponding colors that represent different values. For individuals who are color blind, the use of a resistor-like body with distinct patterns or markings can help distinguish between the colors. This system ensures that even whether dealing with ordinary type resistors or tight tolerance resistors, the color coding remains a common way to provide easy identification of characteristics despite potential color conversion issues.

What is the significance of the resistor color codes that were first introduced in the mid-twentieth century in identifying the characteristics of resistors and capacitors?

The resistor color codes, which were first introduced in the mid-twentieth century, use colored bands to quickly identify a resistor’s resistive value and make it easier to distinguish between different types of ordinary type resistors and their characteristics. This color coding system not only applies to resistors but also to capacitors, helping in understanding variations in ohmic/high voltage resistors. The consistent color schemes, including particular colors like blue color and colors gold, utilize a specific color sequence that aids in recognizing band resistor examples and exceptions for five-band color codes, enhancing the overall identification process in electronic components.

How can I determine the resistive value of an ordinary type resistor using the color code system, particularly how the sequence of colors matters in the colored bands?

The resistor color codes were first introduced in the mid-twentieth century as a color coding system that uses colored bands to quickly identify a resistor’s resistive value. Each color represents a number, and the sequence of colors matters because it determines the value as well as the tolerance of the resistor. For ordinary type resistors, misreading the color code exceptions or the tip color can lead to incorrect identification, which highlights why understanding the color sequence and separate colors is essential in properly reading resistor and capacitor values.

What is the historical importance of the first resistor color coding system and how does the color code system aid in quickly identifying the resistive value of ordinary type resistors using color bands?

The first resistor color coding system was introduced in the mid-twentieth century and has significantly impacted the way we identify resistors. Today, the color code system uses colored bands to quickly identify a resistor’s resistive value. For ordinary type resistors, the color sequence of the bands is crucial, as different colors represent specific values. This allows for easy identification of characteristics in a range of resistors, which has been particularly beneficial since color coding predates many modern identification methods. The system utilizes the color-code backwards to ensure clarity and accuracy in determining resistance values.

How does the band resistor color coding system uses colored bands to quickly identify a resistor’s resistive value?

The band resistor color coding system is a common way to provide easy identification of characteristics of ordinary type resistors. By analyzing the color sequence on the colored bands, one can determine the resistive value, which varies depending on the arrangement and colors displayed. This color coding, which predates modern electronic components, remains a reliable method for quickly identifying resistor values.

What methods can one utilize to confirm that a resistor varies from its specified resistive value, even though the color coding is a common way to provide easy identification of characteristics?

To confirm that a resistor varies from its specified resistive value, you can use a multimeter to measure the resistance directly. This method is particularly helpful for ordinary type resistors, as the resistor may have drifts in value due to factors like heat or age. While the color coding typically uses colored bands to quickly identify a resistor’s resistive value, it’s always good practice to verify through measurement, especially when precise resistance is critical. Remember that if the color sequence on the resistor’s bands is unclear or faded, doing a measurement is essential to ensure accuracy.

What historical advancements led to the creation of the resistor color coding system and how does it use colored bands to quickly identify a resistor’s resistive value?

The resistor color coding system, which uses colored bands to quickly identify a resistor’s resistive value, was developed in response to the need for a standardized method of identifying ordinary type resistors. This color coding system predates many modern developments in electronics and is a common way to provide easy identification of characteristics. The sequence of colors, or color sequence, on the bands is crucial for accurately determining the resistive value of resistors.

What role did early designs of resistor color coding play in the creation of the color coding system that is widely used today, particularly in how it uses colored bands to quickly identify a resistor’s resistive value?

Early designs of resistor color coding laid the groundwork for the modern color code system. This system uses colored bands to quickly identify a resistor’s resistive value, especially for ordinary type resistors. The importance of color sequence in these bands is essential, as correct interpretation is crucial for proper functionality. The development of this color coding is a common way to provide easy identification of characteristics of resistors that predates more complex identification methods.

What are the historical origins of the resistor color coding system and how does it utilize colored bands to quickly identify a resistor’s resistive value, particularly in ordinary type resistors, considering the significance of color sequence and color bands?

The resistor color coding system has significant historical origins that date back to solutions developed when electronic components became prevalent. This system uses colored bands to quickly identify a resistor’s resistive value, which is particularly useful for ordinary type resistors. The color sequence, where each color corresponds to a specific number, combined with the arrangement of the color bands, allows for accurate determination of resistance values, making it a dependable method for identifying resistors that predates many modern identification methods.

How did the development of resistor color coding systems contribute to the understanding of how it uses colored bands to quickly identify ordinary type resistors, especially in the context of resistor history that predates modern electronics?

The development of resistor color coding systems significantly contributed to the understanding of electronic components. This system uses colored bands to quickly identify a resistor’s resistive value, which is essential when working with ordinary type resistors. Understanding the color sequence and the roles of each color band allows individuals to efficiently ascertain the specifications of resistors, uncovering a method that predates many modern electronic practices.