Top 10 Uses of Resistor Color Coding

Table Of Contents

Discover the Top 10 Uses of Resistor Color Coding and Understand Resistor Color Codes

Key Takeaways

- Grasping the basics of resistor color markings

- Leading ten applications of resistor color identification

- Significance of precise resistor color recognition

Understanding Resistor Color Codes

Resistor color coding is essential for identifying the specifications of resistors used in various electronic applications. The resistor color code allows users to quickly determine a resistor’s value and tolerance through a simple color band system. This coding system aids in the classification and selection of both fixed resistors and variable resistors, streamlining assembly and maintenance tasks. Among the Top 10 Uses of Resistor Color Coding, identifying resistor values and tolerances plays a crucial role in circuit design and troubleshooting. Understanding these resistor colour codes enhances communication among engineers and standardizes components across different projects. The RMA resistor color code provides a consistent reference, ensuring accuracy and reliability in electronic devices.

What is a Resistor Color Code?

Resistor color codes serve as a universal system used to identify the values and specifications of various resistors in electronic circuits. These codes consist of colored bands that indicate resistance values, tolerance, and sometimes temperature coefficients. Fixed resistors, variable resistors, power resistors, and light-dependent resistors utilize these marking codes, allowing engineers and technicians to decode essential information at a glance. Familiarity with the electronic color code is vital for anyone working with resistive components such as film resistors and capacitors.

The Top 10 Uses of Resistor Color Coding highlight the significance of accurate interpretation of these codes in both design and practical applications. Understanding color codes enhances the efficiency of assembling and maintaining electronic devices. It aids in identifying the right component for replacement, ensuring optimal performance in circuits. Through the use of resistive elements and clear marking codes for resistors and capacitors, engineers can streamline troubleshooting and enhance communication, ultimately contributing to the reliability and effectiveness of electronic systems.

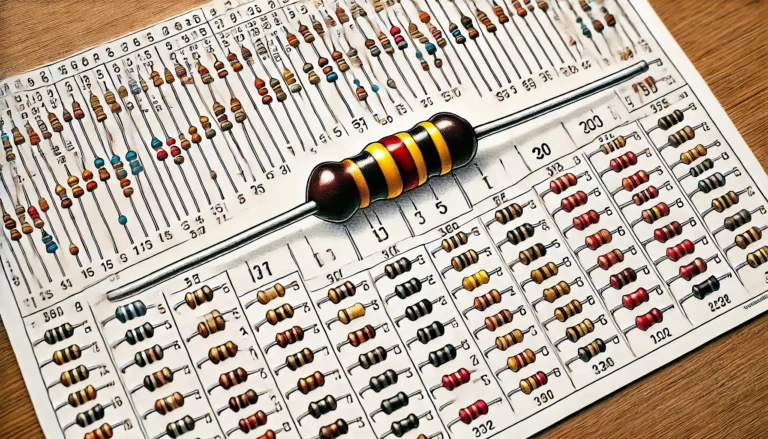

How Resistor Color Codes Work

Resistor color codes are a systematic way to identify the resistance values of various resistors. Each color corresponds to a specific digit or tolerance level, allowing for quick access to resistor specifications without the need for complex calculations. For instance, the electronic colour code uses a series of colored bands, such as those found on wire-wound resistors, to represent resistances and their tolerances. The eia color code and the rma color coded standards ensure consistency across different manufacturers, simplifying the identification process for engineers and hobbyists alike while highlighting some of the Top 10 Uses of Resistor Color Coding.

Understanding how to read color codes can significantly streamline tasks related to electronics. A proper grasp of these codes aids in determining the appropriate resistive load, which is crucial for circuit functionality. For individuals who are color blind, alternative means of identifying resistance values, such as printed labels or digital color readers, help ensure they are not at a disadvantage. This ability to efficiently identify resistors enhances design processes and repair strategies, illustrating the importance of the Top 10 Uses of Resistor Color Coding in various applications.

| Color | Digit/Tolerance |

|---|---|

| Black | 0 |

| Brown | 1 (±1% Tolerance) |

| Red | 2 (±2% Tolerance) |

| Orange | 3 |

| Yellow | 4 |

| Green | 5 (±0.5% Tolerance) |

| Blue | 6 (±0.25% Tolerance) |

| Violet | 7 (±0.1% Tolerance) |

| Gray | 8 |

| White | 9 |

Top 10 Uses of Resistor Color Coding

Resistor color coding serves several vital functions in the realm of electronics, and understanding its practical applications can optimize both design and maintenance processes. One of the Top 10 Uses of Resistor Color Coding is the identification of resistor values, which allows engineers to easily determine resistance without requiring specialized tools. This system also aids in determining the temperature coefficient of resistance, critical for ensuring that circuits perform optimally under varying conditions. For individuals who are color-blind, alternative identification methods can be crucial for working with color-coded components on circuit boards. Furthermore, the role of color coding in adhering to electrical codes, such as the Canadian electrical code, cannot be understated. Clear communication of resistance values enhances circuit design efficiency and fosters collaboration among engineers, particularly in low-voltage applications. Ultimately, the Top 10 Uses of Resistor Color Coding facilitate reliable electronic circuit design and contribute to streamlined production processes across the industry.

Identification of Resistor Value

Resistor color coding serves as a reliable method for identifying resistor values, which is essential for building electronic circuits. Each color on a color-coded resistor corresponds to a specific number, allowing engineers and hobbyists to determine the resistance value without additional tools. This knowledge is crucial in applications such as printed-circuit boards (PCBs), where precise resistance is vital for optimal performance. Understanding the resistor color code enhances efficiency in troubleshooting and modification of circuits, contributing to the top 10 uses of resistor color coding.

Color-coded resistors not only assist in identifying resistance values but also play a role in accommodating individuals with colour blindness. The clear visual representation of resistor values simplifies the process of working with electronic circuits, making it easier for a wider audience to participate in design and repair tasks. Misinterpretations can lead to poor circuit performance, emphasizing the importance of accuracy in resistor color identification within the top 10 uses of resistor color coding. Knowledge of these coding systems is integral to achieving desired outcomes in projects that leverage principles like the photoelectric effect.

Determining Resistor Tolerance

Resistor tolerance is a critical aspect of electronic components that directly affects circuit performance. The resistor color bands on the component reveal not only the resistor values but also the acceptable range of variation, which is indicated through specific band resistor colors. This flexibility in resistor color coding allows engineers to choose top resistor options based on their project requirements. Understanding these distinctions within the multi-purpose resistor code can aid in making informed decisions about which components to use, ensuring that the intended design operates effectively.

The antique resistor color codes still hold significance today, especially with the rise in vintage electronics. Knowing how to read resistor symbols can help hobbyists and professionals accurately identify the resistor tolerance. Variations in the rma resistor color can indicate small differences in performance that may be critical to circuit integrity. Understanding the top 10 uses of resistor color coding, including tolerance determination, is vital for troubleshooting and optimizing electronic designs. Resistor-like components may sometimes complicate matters, but proper identification ensures quality and reliability.

Facilitating Repair and Replacement

Repair and replacement of resistors can become significantly more efficient through understanding the Top 10 Uses of Resistor Color Coding. Knowing the resistor symbol and its corresponding color bands enables technicians to quickly identify common resistor values, such as those found in small resistors and metal film resistors. This allows for a straightforward selection of appropriate resistor standard values, including e96 resistor values, ensuring compatibility with existing circuit designs. Recognizing these values helps speed up the repair process while minimizing the risk of errors.

For specialized resistors, including variable resistor serves and high-voltage resistors, accurate color code identification is crucial. Technicians can easily match the resistive element specifications with the correct resistor package. This not only streamlines the replacement process but also enhances the reliability of circuits. By utilizing the insights from the Top 10 Uses of Resistor Color Coding, engineers and repair personnel can maintain high standards in component replacement, leading to improved circuit performance and durability.

Aiding in Circuit Design

Resistor color coding plays a crucial role in aiding circuit design by providing an efficient method for identifying resistive values. Using a band resistor example, designers can quickly determine the specifications of high precision resistors like thin film resistors or high voltage resistors. With the advanced use of 5-band and 6-band resistor configurations, engineers can accurately select components that meet specific requirements, ensuring optimal performance in their circuits. The quick identification of resistive values streamlines the design process and reduces potential errors in selecting components.

For designers, having access to tools like an automatic resistor calculator enhances the design experience. This tool simplifies the process of calculating and verifying resistor values, particularly useful when working with old style resistors or when developing new prototypes. Accurate identification of resistive values is one of the Top 10 Uses of Resistor Color Coding, allowing for better planning and execution of electronic projects. By facilitating precise component selection, resistor color coding ultimately supports innovative and efficient circuit designs.

Educational Tool for Beginners

Understanding resistor color coding serves as an invaluable educational tool for beginners in electronics. Many learners start with composition resistors, which typically feature a color-coded band system. By recognizing the significance of each color, new engineers or hobbyists can identify the resistance values and tolerances of 5-band and 6-band resistors. This foundational knowledge is crucial when working with various resistors, including ohmic/high voltage resistors and precision resistors. Beginners can directly utilize this understanding to navigate through the Top 10 Uses of Resistor Color Coding.

Another essential aspect of learning resistor color coding involves the application of online resistor calculators. These tools help beginners confirm their manual calculations and develop confidence in identifying resistor values. Engaging with this technology not only solidifies their understanding of tight tolerance resistors but also aids in recognizing the differences between SMD resistors and standard resistors body sizes. Overall, mastering color coding paves the way for deepening knowledge in resistor applications, reflecting the significance of the Top 10 Uses of Resistor Color Coding.

Streamlining Production Processes

The integration of a color coding system in the production of electronic components aids manufacturers in efficiently categorizing resistors. By utilizing the standard color codes, teams can quickly identify preset resistors, band resistors, and large power resistors during assembly. This process minimizes confusion and errors, ensuring that components like mighty resistors, carbon composition resistors, and oxide resistors are placed accurately. A streamlined production process enhances overall productivity and reduces the chances of defective assemblies.

Incorporating the Top 10 Uses of Resistor Color Coding within manufacturing protocols leads to significant improvements in quality assurance. Utilizing the standard color code for various resistor types allows for quicker verification of specifications and performance. Employees become adept at recognizing color codes, which simplifies the handling of materials and expedites the assembly process. This efficiency ultimately contributes to faster turnaround times and better resource management in electronics production.

Ensuring Quality Control

Quality control in electronics heavily relies on accurate resistor color coding. Technicians utilize color-coded bands to quickly identify the resistance values of components, such as a 2-kilohm resistor. This practice helps ensure that cylindrical composition resistors meet specifications and function correctly. The implementation of a color code calculator can streamline this process, allowing engineers to verify band color code and colored tolerance band compatibility. Accurate identification directly impacts performance, reducing errors in production.

Manufacturers prioritize quality control by meticulously checking the color boundaries on components. Misinterpretation of resistance values can lead to circuit failures, affecting overall system reliability. By establishing strict protocols for the identification of rma resistors, organizations can maintain high standards in their production lines. Quality checks involving adjustable resistance settings enhance the accuracy of performance tests. The significance of resistor color coding is undeniably one of the Top 10 Uses of Resistor Color Coding in maintaining industry standards.

Assisting in Troubleshooting

Troubleshooting electronic circuits often requires quick identification of components, making resistor color coding invaluable. By consulting a color code chart, engineers can determine the specific resistance value of resistors with different color bands. Accurate identification helps prevent errors in circuit design, leading to effective resolution of issues. A clear understanding of tolerance codes is essential for analyzing how variable resistance affects overall circuit performance.

Interpreting resistance results accurately is critical during diagnostics. Using the common color sequences to identify the final resistance value enables engineers to troubleshoot problems systematically. Confusion can arise from misreading resistor colors, especially when multiple resistors exhibit the same resistance. The Top 10 Uses of Resistor Color Coding highlight its importance in ensuring each component functions correctly within the circuit to maintain desired outcomes.

Enhancing Communication Among Engineers

Resistor color coding serves as a universal language among engineers, facilitating clear communication about components. The standardization of colors, such as the 5-band color system, allows for a straightforward interpretation of resistor values and tolerances. Certain colors represent specific numerical values, while ring colors, like gold and silver, denote tolerance levels. This consistency in color bands ensures that engineers can easily convey critical information about actual resistance and avoid miscommunication in technical documentation and discussions.

Understanding the Top 10 Uses of Resistor Color Coding is essential for streamlining collaboration. Engineers can quickly identify the resistance changes needed for circuit modifications by referencing the different color bands. The clarity provided by the rma color system and the precise categorization of colours enhances teamwork on projects. By adhering to established color codes, engineers can efficiently share insights and solutions, reducing the likelihood of errors and improving overall project outcomes.

Standardizing Components in Electronics

Resistor color codes play a vital role in standardizing components in the electronics industry. These codes ensure that engineers and technicians can easily identify the preferred resistance values of resistors, thanks to the particular colors representing different numerical values. The third color in the code indicates tolerance, which is crucial for ensuring effective resistance in high-precision circuits. Such standardized marking codes allow for consistent communication across designs and applications, reducing confusion during assembly on printed-circuit boards.

High-power applications also benefit from the standardization brought by resistor color coding. The color of the resistor body not only signifies its resistance but also assists in determining its suitability for specific tasks, like voltage divider circuits. By adhering to these universally recognized color codes, manufacturers and engineers can streamline their production processes and enhance quality control. The Top 10 Uses of Resistor Color Coding highlight the importance of maintaining consistency, ensuring that components meet the desired specifications, and ultimately improving the reliability of electronic devices.

Importance of Accurate Resistor Color Identification

Accurate identification of resistor colors is crucial for maintaining optimal circuit performance. The colour stripes on resistors, which indicate their value and tolerance, play a vital role in the Top 10 Uses of Resistor Color Coding. Misinterpretation can arise from non-standardised jacket colors or confusion with thermocouple wires. Understanding the different codes represented by coloured rings is essential to avoid mistakes that could lead to low-tolerance issues. The gold tolerance band and white tolerance ring signify important information about resistors, and failure to recognize these properly can impact the functionality of electronic devices. Knowledge of these color codes ensures that engineers communicate effectively and maintain quality control, thereby maximizing the efficiency of electronic components.

Impacts on Circuit Performance

Accurate resistor color coding plays a critical role in the performance of electronic circuits. The Top 10 Uses of Resistor Color Coding highlight the importance of correctly identifying resistor values, especially in calibration circuits and transistor circuits. Using numeric codes or a 6-digit code ensures precise resistance levels are maintained, allowing for optimal low inductance and voltage rating class performance. Misinterpretation can lead to incorrect component values, potentially causing circuit failures or subpar performance.

Understanding resistor color codes is essential for engineers and hobbyists alike, including color-blind people who may face challenges in interpreting resistor values. The inclusion of gold tolerance within these codes provides additional reliability and informs users of acceptable variations in resistance. Correctly implementing this coding system allows for seamless design processes and consistent communication among engineers, ultimately enhancing the overall functionality of electronic devices.

- Understanding resistor values helps in selecting appropriate components for specific applications.

- Accurate color coding aids in troubleshooting and repairing circuits.

- Proper identification reduces the risk of component mismatch in complex designs.

- The color coding system is essential for maintaining consistency in mass production.

- Familiarity with these codes promotes better education and skills among new engineers.

- Recognizing tolerance levels helps in choosing resistors suitable for varying environmental conditions.

- Adopting standardized coding enhances collaboration within teams and across companies.

Avoiding Common Misinterpretations

Misinterpretation of the resistor color code can lead to incorrect values being assigned to components. This issue often arises in high-frequency applications where the tolerance of resistors is critical. Engineers must be particularly careful with small inductors and their associated codes because even slight errors can impact a circuit’s performance. For those dealing with tight tolerance values, a misread can result in significant deviations, affecting the overall circuit response.

Another aspect to consider is the ppm/°c ratings associated with resistors. Misunderstanding these ratings could lead to poor thermal performance and reliability. Tight tolerance resistors are crucial for circuits that require precise fine-tuning. Wires and connections that are not carefully matched to the resistor specifications can exacerbate these problems. Recognizing the Top 10 Uses of Resistor Color Coding helps in mitigating these risks and promoting accuracy in electronic design.

Conclusion

Resistor color coding plays a pivotal role in the realm of electronics, enabling engineers and hobbyists to identify essential resistor characteristics quickly. The Top 10 Uses of Resistor Color Coding highlight its significance in tuning circuits, ensuring high precision in various applications. Each resistor displays colored stripes, which represent its value and tolerance—elements crucial for circuit design and functionality. Mastering these codes allows for efficient troubleshooting, enhances communication among engineers, and standardizes components within the industry, ultimately leading to improved performance and reliability in electronic devices. Understanding these principles reinforces the importance of accurate resistor identification in achieving optimal circuit performance.

FAQS

How does resistor color coding help in identifying precise resistance values in resistors used on a printed circuit board (PCB)?

Resistor color coding is crucial as it allows for easy identification of the resistors’ precise resistance values. The colored rings on the resistor indicate numerical codes that correspond to specific resistance values. For example, a 5-band resistor uses a more flexible resistor color scheme to provide better accuracy. This is especially useful in applications involving light-dependent resistors or wire wound resistors, ensuring that designers can effectively integrate them into a printed-circuit board (PCB). Additionally, different colors like gold can assist color blind people in distinguishing between the intended values, thus ensuring reliability in a particular circuit.

What are some practical applications of resistor color coding for identifying components like light dependent resistors and 5-band resistors on a printed circuit board (PCB)?

Resistor color coding is essential for identifying various resistive materials and components, such as light dependent resistors and 5-band resistors, on a printed circuit board (PCB). The color code resistors follow a standardized 25-pair color code, which helps in determining the resistance values quickly. This coding includes colors such as gold, which indicates tolerance, and the body color that signifies the resistor’s type. Understanding resistor color coding uses makes it easier for engineers and technicians to navigate PCBs efficiently.

What are the benefits of using resistor color coding in components with a resistor-like body, especially when it comes to distinguishing ohm resistors with colors like gold?

Resistor color coding provides a systematic way to read and identify the resistance values of components, including those with a resistor-like body. By using the specific colors, such as gold for tolerance, circuit designers can easily calculate the exact ohm resistors’ values, ensuring precise functionality and reliability in electronic applications.

What is the significance of using colors like gold in resistor color coding?

The significance of using colors like gold in resistor color coding lies in their ability to indicate the tolerance of resistors, which is important for precision in electronic circuits. The colors gold and others help distinguish between different resistor values effectively.

What methods can be employed to effectively teach resistor color coding to beginners who are building their first printed circuit board (PCB)?

To effectively teach resistor color coding to beginners building their first printed circuit board (PCB), educators can use hands-on activities, visual aids, and interactive tools that help students understand the importance of color bands in identifying resistance values. Using practical examples, like the identification of standard resistors and demonstrating the use of multimeters, can further enhance the learning experience.