Aluminum Busbars

Understanding Aluminum Busbars: A Comprehensive Guide to Aluminum Bus Bars and Their Applications

Key Takeaways

- Summary of Aluminum Busbars and their characteristics

- Varieties of Aluminum Busbars and their classifications

- Conductive properties of Aluminum Busbars and their significance

- Contrast with Copper Busbars and their performance differences

- Choosing the appropriate Busbar material and considerations

- Busbar products and their various uses in applications

Overview of Aluminum Busbars

Aluminum busbars serve as critical components in electrical systems, enabling the efficient distribution of electrical power. These bus bars, made from aluminum, provide a lightweight yet robust alternative to traditional copper busbars. The design and function of aluminum busbars allow for effective heat dissipation, enhancing overall performance in various applications. Used extensively in bus ducts and power distribution systems, aluminum busbars offer significant advantages such as lower installation costs and higher conductivity, making them a popular choice in many industries. With their unique properties, aluminum busbars continue to play a vital role in modern electrical infrastructure.

Definition and Function of Busbars

Aluminum busbars are essential components in electrical systems, commonly used to distribute power efficiently. They serve as conductive paths, allowing electricity to flow from one point to another within a circuit. The use of aluminum alloys in these busbars enhances their strength and conductivity, making them ideal for various applications. Aluminum can withstand high temperatures and corrosion, factors that contribute to their longevity and reliability in demanding environments.

These bus systems are frequently installed in busways, which are metal enclosures that house the busbars. Aluminum wire is often connected to busbars to facilitate seamless power distribution. According to aluminum.org, the advantages of utilizing aluminum busbars over other materials include reduced weight and lower costs, making them a preferred choice in many industrial and commercial settings.

Advantages of Using Aluminum Busbars

Aluminum Busbars offer significant benefits in various electrical applications due to their lightweight nature. The use of aluminum conductor reduces the overall weight of power distribution systems, making them ideal for transportation and vehicle applications. The 6061 aluminum used in these busbars provides excellent strength-to-weight ratios and increased corrosion resistance, ensuring longevity and reliability in demanding environments. The incorporation of copper clad aluminum further enhances conductivity, combining the advantages of both materials in a single solution.

Another key advantage lies in the cost-effectiveness of aluminum busways. Compared to traditional copper alternatives, 6061-T6 aluminum busbars can be produced at a fraction of the cost, making them more accessible for large-scale projects. Their efficiency in energy transmission minimizes power losses, which translates into reduced operational costs over time. These features make aluminum busbars an attractive choice for industries focused on optimizing both performance and budget.

Types of Aluminum Busbars

Aluminum Busbars are essential components in various electrical systems, offering distinct types to suit different applications. Standard Aluminum Busbars are widely used for their reliable performance in distribution boards and switchgear assemblies. Flexible aluminum bus options cater to unique installations, particularly in vehicles where space constraints and movements demand adaptability. Incorporating copper-clad aluminum wire enhances conductivity while reducing weight, making them ideal for aerospace applications. These bus conductors exhibit superior strength when combined with metals, allowing for efficient use in environments requiring precision, such as those utilizing press brakes. The selection of the right type of aluminum busbars can significantly impact overall system efficiency and durability.

Standard Aluminum Bus Bars

Aluminum busbars are essential components in electrical systems, serving as a reliable means to conduct electricity in various infrastructures. They are often engineered with high-quality materials, such as silicone rubber, to enhance their insulation and durability. These busbars—aluminum are designed specifically for critical infrastructure applications, where resistance to high temperatures and mechanical stress is crucial. Their lightweight nature makes them a preferred choice for many setups, particularly where space and weight constraints are present.

The reliability of aluminum busbars extends to their ability to integrate seamlessly with braking systems and other electrical applications. The choice of aluminum busbars can significantly impact the overall efficiency of electrical distribution, making them a vital element in modern electrical design. Their versatility allows for easy customization, adapting to the unique demands of any project while ensuring optimal performance. As technology continues to advance, the use of these busbars in innovative applications is expected to grow even further.

Flexible Aluminum Bus Options

Flexible aluminum bus options provide an innovative solution for various electrical applications that require adaptability and efficiency. These aluminum busbars are designed to be lightweight yet robust, allowing for easier installation and maintenance compared to traditional rigid busbar systems. The flexibility of these aluminum bus bars enhances their ability to fit into tight spaces while maintaining excellent conductivity. This makes flexible conductive aluminum busbars ideal for environments where traditional setups might be impractical.

The series of aluminum busbars utilized in flexible applications can accommodate dynamic load conditions found in modern electrical systems. The design and construction of the aluminum busbar system ensure a stable performance, delivering reliable power distribution across a range of industries. Users benefit from the efficient heat dissipation and reduced risk of thermal expansion issues associated with flexible aluminum busbars, making them a favored choice for both commercial and industrial sectors.

Conductive Aluminum Busbars

Conductive aluminum busbars serve as critical components in electrical systems, offering efficient conductivity and reliable performance. These aluminum bus products are designed to handle high current loads while maintaining a compact form factor. The versatility of aluminum makes it a popular choice, with options available as solid busbar or custom aluminum bus configurations to meet specific project needs. Their lightweight nature enhances ease of installation, providing significant benefits over traditional busbar materials. With the capability to generate quick quotes for aluminum busbars, businesses can streamline their purchasing process while ensuring they receive the top aluminum bus products suitable for various industries. Effective applications can be found across multiple sectors, highlighting the utility and importance of aluminum busbars in modern electrical systems.

Properties and Benefits

Aluminum Busbars are known for their excellent electrical conductivity, making them a prime choice in various busbar systems. These busbars are significantly lighter than copper busbars, allowing for easier handling and installation. The efficiency of aluminum in busbar construction also leads to lower energy losses in electrical systems. This property is crucial for ensuring optimal performance of electrical aluminum bus products across a range of applications.

The benefits of using Aluminum Busbars extend beyond weight and conductivity. They exhibit high corrosion resistance, enhancing the longevity of busbar products in challenging environments. This durability reduces maintenance costs and increases reliability in electrical applications. Choosing the right busbar material is essential for achieving both performance and cost-effectiveness, reinforcing the growing preference for aluminum in busbar manufacturing and design.

Applications for Conductive Aluminum Busbars

Aluminum Busbars are widely utilized in various electrical systems due to their excellent conductivity and lightweight properties. The busbar offering includes options tailored for specific needs, such as electrical aluminum bus configurations for distributing power efficiently. Industries increasingly rely on cu-al busbar solutions for their robustness and cost-effectiveness. For each next busbar application, careful consideration is needed to ensure optimal performance and safety standards are met.

Battery busbars represent a significant area of application for Aluminum Busbars, particularly in renewable energy sectors and electric vehicles. The demand for high-performance busbar production is rising, leading to innovative designs that enhance electrical connections. In every next busbar project, engineers strive to maximize efficiency and minimize losses, making aluminum an attractive choice for future electrical installations.

Comparison with Copper Busbars

Aluminum busbars offer distinct advantages over their copper counterparts, making them a popular choice in various electrical applications. The lightweight nature of aluminum busbars allows for easier installation and handling, especially in short busbar configurations. Flexible busbar options enhance adaptability in tight spaces and complex layouts, facilitating seamless integration into existing systems. Cost-effective electrical busbar products often employ aluminum as the primary bus bar material, reducing overall project expenses. While copper bus bars are known for their conductivity, aluminum options, such as braided busbars, provide sufficient performance for many industrial applications. Ultimately, the choice between aluminum and copper hinges on specific project requirements and budget considerations.

Cost-Effectiveness of Aluminum vs. Copper

Aluminum Busbars present a cost-effective alternative to copper busbars, particularly in large-scale electrical installations. With a lower raw material cost, aluminum offers manufacturers the ability to fabricate bus bars at a reduced expense. The lighter weight of aluminum components allows for easier handling and installation. A thicker bus bar made of aluminum typically provides comparable conductivity to copper, making it a practical choice for many applications.

The use of multiple bar bus systems also favors aluminum due to its affordability. Aluminum products benefit from lower overall production costs, which can significantly reduce expenses in extensive projects. By opting for Aluminum Busbars, businesses can achieve both performance and savings, leading to a favorable return on investment. The combination of these advantages positions aluminum as a strong contender in the busbar market.

Performance Differences

Aluminum Busbars exhibit distinct performance characteristics that set them apart from their copper counterparts. The lightweight nature of aluminum allows for easier handling and installation, especially in rectangular bar bus configurations. This can help reduce overall installation costs. The effectiveness of aluminum connectors in facilitating secure connections enhances the reliability of the entire electrical system. Proper bus bar fabrication techniques ensure that the aluminum component maintains its integrity under various operational conditions, which is crucial for long-term performance.

Conductivity is a vital aspect of busbar performance. While copper typically has better conductivity, Aluminum Busbars can offer acceptable performance levels for many applications when designed correctly. The use of bus bar fasteners and connectors plays a significant role in maximizing conductivity. It is essential to select the correct bus bar for your specific needs to avoid potential issues. The balance between cost, weight, and necessary performance can make aluminum solutions an appealing choice in various settings.

Selecting the Right Busbar Material

Choosing the appropriate material for bus systems involves understanding various options available. Aluminum busbars are a popular choice due to their lightweight nature and excellent conductivity. Aluminum means that energy losses are minimized, making it an efficient option for many applications. The aluminum profile allows for customization, with custom aluminum solutions available to fit specific design requirements. Compared to its copper counterpart, aluminum varies in advantages, particularly in cost and weight. Importantly, aluminum conducts electricity effectively, ensuring reliable performance. Considering these factors is essential for determining the best material for your specific needs.

Factors to Consider

Selecting the right type of Aluminum Busbars necessitates a thorough evaluation of several key factors. The specific requirements of busway systems play a crucial role, as they dictate not only the design but also the material specifications. Options like round angle aluminum enhance structural integrity, while hot selling aluminum continues to gain traction for its affordability and versatility in various applications. It is essential to consider the electrical grade aluminum used in manufacturing, ensuring it meets industry standards for conductivity and performance.

Another significant aspect is the aluminum fabrication process, which directly impacts the quality and durability of the busbars. High-quality aluminum fabrication delivers products that can withstand various environmental conditions and mechanical stresses. For applications requiring enhanced performance, incorporating cca bus features can further optimize efficiency and effectiveness. Ultimately, assessing these factors will lead to informed decisions about the most suitable Aluminum Busbars for any electrical project.

Aluminum Bus Bar vs. Other Materials

Aluminum busbars stand out among various materials due to their favorable properties and lower pure aluminum rates. These conductive buses are lightweight yet capable of supporting equivalent loads compared to heavier options. Flat bars and panels made from aluminum are often preferred for electrical systems, as their efficient design minimizes transportation costs and installation challenges. The ability to customize aluminum busbars for specific applications enhances their appeal in diverse sectors.

Comparison with materials such as copper reveals that aluminum busbars offer significant advantages. While copper is known for its excellent conductivity, aluminum provides a cost-effective alternative without sacrificing performance. The unique characteristics of aluminum allow for the development of lightweight bars that maintain high strength and durability. As industries continue to seek efficient solutions, aluminum busbars remain a go-to choice for electrical infrastructure and design.

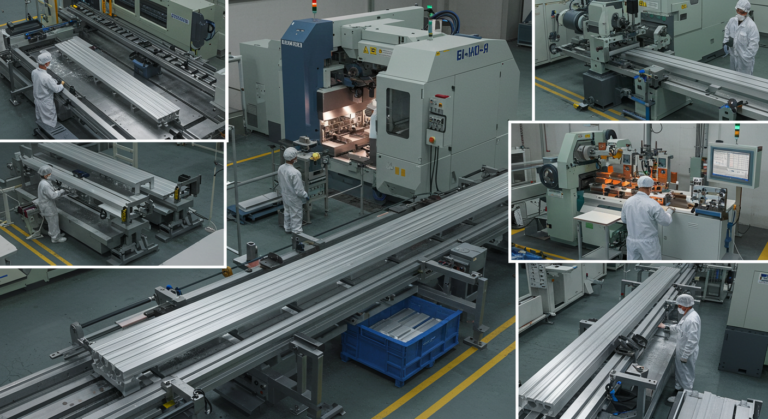

Busbar Products and Applications

Aluminum Busbars are essential components in various electrical systems, offering significant advantages due to their high-purity form aluminum. These busbars can achieve steel-like strength while maintaining a lightweight profile, making them particularly suitable for automotive applications where reducing weight is critical. The thickness of these conductive strips ensures efficient electricity distribution in equipment across different industries. Their flat bar design enhances adaptability, allowing for seamless integration into existing systems, which is particularly advantageous in both industrial and automotive sectors. As a result, Aluminum Busbars have become increasingly popular in applications that require robust performance without the added weight.

Common Uses in Electrical Systems

Aluminum Busbars serve a pivotal role in various electrical systems, providing a reliable means of conducting electricity. Their lightweight nature and ability to withstand high currents make them a preferred choice for many applications. Commonly found in power distribution panels, switchgear, and substations, these bars facilitate efficient transmission of power while minimizing energy loss. The outer structure of Aluminum Busbars is designed to enhance thermal dissipation, ensuring optimal performance in demanding environments.

The versatility of Aluminum Busbars extends across numerous sectors, from commercial buildings to industrial facilities. These materials are often utilized in renewable energy applications, such as solar and wind power systems, where effective power distribution is crucial. Electric vehicles and transportation infrastructure also rely on Aluminum Busbars, as they enhance energy efficiency and reduce overall weight. Their adaptability and performance continue to drive innovation in electrical engineering and systems design.

Industries Utilizing Aluminum Busbars

Aluminum busbars are extensively used in various industries due to their exceptional conductivity and lightweight properties. These busbars offer a reliable solution for power distribution in electrical systems, replacing traditional copper options in many applications. The use of aluminum alloys enhances their strength and resistance to corrosion, making them ideal for demanding environments. Resources like aluminum.org highlight the effectiveness of aluminum wire in conjunction with busways, ensuring safety and efficiency in electrical installations.

The transportation sector is one of the prominent industries utilizing aluminum busbars, particularly in electric buses. The lightweight nature of aluminum can significantly reduce the overall weight of the vehicle, leading to improved energy efficiency. Many industrial applications also benefit from aluminum busbars, offering streamlined power solutions for manufacturing and processing facilities. These busbars contribute to operational efficiency by reducing energy loss within the system while maintaining robust performance throughout their lifespan.

Conclusion

Aluminum busbars play a crucial role in modern electrical systems, providing efficient and reliable pathways for electrical current. The advantages of aluminum bus, including lightweight properties and excellent conductivity, make them a preferred choice for many applications. Top aluminum bus solutions can outperform traditional materials while offering a more cost-effective option. Businesses often seek custom aluminum bus configurations to meet specific needs, ensuring that their systems operate smoothly and safely. With the growing demand for effective busbar materials, solid busbar designs are increasingly favored for their durability and performance. Exploring options like aluminum busbars ensures that industries can optimize their electrical infrastructure, leading to enhanced efficiency and reduced operational costs.

FAQS

What are the advantages of using aluminium busbars over their aluminum counterparts in electrical applications?

Aluminium busbars offer several advantages compared to aluminum counterparts, including lighter weight, which is particularly beneficial for automotive lightweight designs. In addition, series aluminium busbars can handle equivalent loads efficiently while maintaining high-purity form aluminium, making them a preferred choice in many electrical applications. For those looking to procure these products, quick quote options are available for both aluminium bus and bus bar connectors.

How can I obtain a quick quote for aluminum busbars designed for handling equivalent loads in electrical systems?

You can get a quick quote for aluminum busbars by submitting a request through our products page, specifically tailored for electrical aluminum bus applications. Our team will assist you with the specifications and provide options that match your requirements for handling equivalent loads in your electrical systems.

How can I ensure that the aluminum busbars I choose are suitable for handling equivalent loads in my electrical system when seeking a quick quote?

To ensure that the aluminum busbars you select can handle equivalent loads in your electrical system, it’s important to consult suppliers for a quick quote that details the specifications of their products. Look for electrical aluminum bus options that are rated for your required load capacities. When requesting a quote, make sure to specify your needs regarding busbars to find the most suitable aluminum bar for your applications.

What steps should I take to receive a quick quote for products like aluminum busbars that can handle equivalent loads in my electrical system?

To receive a quick quote for aluminum busbars, first identify your specific requirements regarding the products. Make sure to include information about the equivalent loads your electrical aluminum bus system needs to handle. Many suppliers offer quick quotes through online forms where you can input details about your project to facilitate a fast response.

How can I compare the prices of aluminum busbars to obtain a quick quote for different products that can handle equivalent loads in my electrical systems?

To compare prices and obtain a quick quote for aluminum busbars, you should contact multiple suppliers who specialize in electrical aluminum bus products. Make sure to provide them with specifications regarding equivalent loads your application requires, as this will help them offer you accurate pricing on the busbars suitable for your needs.

What considerations should I keep in mind when looking for products like aluminum busbars that can manage equivalent loads for electrical applications during a quick quote process?

When seeking a quick quote for products like aluminum busbars that can handle equivalent loads in your electrical aluminum bus systems, it’s important to consider factors such as the busbar’s specifications, material quality, thermal performance, and the manufacturer’s reputation to ensure that you receive the best possible options.

How do I find manufacturers that offer aluminum busbars for quick quotes on products suitable for handling equivalent loads in electrical systems?

To find manufacturers that provide aluminum busbars, you can start by searching online for suppliers that focus on electrical aluminum bus products. Look for companies that emphasize quick quote services and ensure that their busbars are rated for handling equivalent loads. This will help you get the best options for your electrical systems.

How can I find suppliers that provide quick quotes for aluminum busbars suitable for handling equivalent loads in electrical systems?

To find suppliers that offer a quick quote for aluminum busbars, you can start by researching manufacturers and distributors that specialize in electrical aluminum bus products. Make sure to request detailed information about their products to ensure they meet the requirements for handling equivalent loads in your electrical systems.

What should I look for when evaluating the performance of aluminum busbars in handling equivalent loads before requesting a quick quote?

When evaluating the performance of aluminum busbars, you should consider their conductivity, thermal performance, and mechanical strength to ensure they meet your requirements. Ensuring the products are reliable in your electrical applications is essential, especially when obtaining a quick quote for aluminum busbars that can handle equivalent loads effectively.

What should I consider regarding the electrical performance of aluminum busbars before I request a quick quote?

When evaluating aluminum busbars for their electrical performance, it’s essential to assess their capability to manage equivalent loads effectively. This evaluation ensures that the products you are considering will perform optimally in your electrical system before you proceed to request a quick quote. Look for specifications related to current capacity and resistance loss in the aluminum busbars, as these factors will significantly impact their reliability in handling electrical loads.