Expert Aluminum Busbar Manufacturing for Superior Performance

Expert Aluminum Busbar Manufacturing for Superior Performance revolves around the precise creation of busbars tailored to meet high demands across various industries. Key components include aluminum and aluminum alloys, which provide excellent conductivity while remaining lightweight compared to traditional steel options. The manufacturing process utilizes advanced machinery and techniques to ensure optimal performance and durability, particularly in heavy machinery applications. By focusing on quality and innovative practices, manufacturers can enhance the functional capabilities of electrical busbars, ensuring they meet stringent operational standards. This commitment to excellence in aluminum busbar production establishes a reliable foundation for diverse energy distribution needs.

Expert Aluminum Busbar Manufacturing for Superior Performance | Understanding Aluminum Busbars

Aluminum busbars play a crucial role in electrical distribution systems across various industries, including the aerospace sector. Expert aluminum busbar manufacturing for superior performance emphasizes the need for precise metal fabrication techniques and high-quality materials. Using advanced machines and CNC machining processes, manufacturers are able to achieve the required tolerances and finishes essential for reliable busbar functionality. This level of precision engineering not only enhances performance but also ensures that components can withstand the demanding conditions typical in aerospace applications.

Quality control is a key component in the manufacturing process of aluminum busbars. Rigorous testing and inspection are conducted to guarantee that each product meets industry standards and customer specifications. The use of mild steel components in conjunction with aluminum allows for optimized weight and strength, crucial for applications in the aerospace industry. Factories specializing in expert aluminum busbar manufacturing incorporate advanced technologies and skilled craftsmanship to deliver solutions that meet the high-performance demands of modern electrical systems.

| Busbar Type | Material | Application | Max Current Rating (A) | Weight (kg/m) |

|---|---|---|---|---|

| Flat Busbar | Aluminum | Aerospace Electrical Systems | 500 | 0.5 |

| Round Busbar | Aluminum | Industrial Power Distribution | 800 | 0.8 |

| Split Busbar | Aluminum and Mild Steel | Transportation | 600 | 0.75 |

| High-Voltage Busbar | Aluminum | Utility Grids | 1200 | 1.2 |

Importance of Quality in Manufacturing

Quality in manufacturing plays a crucial role in the performance and durability of aluminum busbars. Expert aluminum busbar manufacturing for superior performance ensures that manufacturers adhere to strict specifications. Engineers rely on precision and reliability, especially in demanding applications like automotive and transportation sectors. The use of advanced techniques such as alloying and silver plating enhances the electrical conductivity and longevity of the busbars, addressing the operational efficiency needs of various industries, including warehouses and public transportation.

Selecting a reputable manufacturer is vital for achieving high-quality aluminum busbars. Knowledgeable manufacturers understand the importance of meeting rigorous standards and specifications. They employ innovative methods to meet the unique requirements of vehicles, buses, and industrial infrastructures. By prioritizing quality throughout the production process, manufacturers contribute to the overall operational efficiency and reliability of the final products, ensuring that they meet the expectations of engineers and end-users alike.

Choosing an Aluminum Busbar Manufacturer

Selecting the right manufacturer for aluminum busbars involves evaluating several critical factors that influence product quality and performance. Expert Aluminum Busbar Manufacturing for Superior Performance hinges on the use of high-grade alloys and metals, which ensure superior mechanical strength to withstand various mechanical stresses. A reputable manufacturer will also implement proprietary design techniques that focus on accuracy and precision, essential for applications in the electrical and electronics industries. The inclusion of silver coatings can enhance conductivity, contributing to reliability in demanding environments. Prioritizing these elements will lead to optimal solutions tailored to specific needs, ensuring that your aluminum busbars provide the performance and durability required for any project.

Factors to Consider When Selecting a Manufacturer

Selecting the right manufacturer is crucial for achieving expert aluminum busbar manufacturing for superior performance. Key factors include the manufacturer’s reputation and experience in the industry. A well-established aluminum busbar manufacturer should demonstrate a track record of producing high-quality aluminum busbars. Consider their capabilities in custom busbar manufacturing, as tailored solutions can significantly enhance the performance of conductors in various electronics applications. Precision busbar manufacturing ensures that the busbars meet stringent quality standards and specifications.

Cost is also an essential consideration, but it should not be the only determining factor. Look for aluminum busbar manufacturers that offer a balance between quality and affordability. Evaluate the availability of various products, including top aluminium busbar options that cater to different project requirements. Assessing customer support and service responsiveness will ensure that you receive expert assistance throughout the manufacturing process. Prioritizing these factors leads to a successful partnership and reliable outcomes in busbar manufacturing.

Leading Aluminum Busbar Manufacturers

Leading manufacturers in the field of aluminum busbars specialize in delivering robust aluminum busbars designed for various applications. These companies focus on expert aluminum busbar manufacturing for superior performance, ensuring that each product meets rigorous standards. They offer a variety of options, including customized aluminum busbars tailored to specific needs. High-quality aluminum bus bars, such as flat aluminum busbars, stand out in the market for their durability and efficiency, and can often be found available for purchase online.

A reliable busbar manufacturer provides innovative solutions, including lab-tested aluminum busbars to guarantee safety and reliability. Additionally, these manufacturers may also offer copper-to-aluminum busbars and steel busbars for diverse electrical configurations. By utilizing advanced technology and quality materials, leading manufacturers shape the future of power distribution with performance-driven products. Purchasing from these trusted sources ensures access to superior aluminum busbars that support an array of industrial demands.

Aluminum Busbar Capabilities

Expert Aluminum Busbar Manufacturing for Superior Performance relies heavily on understanding the diverse capabilities in busbar production. These capabilities include specific busbar fabrication techniques that cater to intricate busbar designs, ensuring each component meets the precise demands of various applications. High-quality busbars can be produced in standard sizes, but specialized busbars are increasingly in demand for tailored solutions. The use of advanced busbar technology enhances the efficiency of manufacturing processes, allowing for the creation of efficient busbars that deliver optimal performance. Manufacturers must prioritize certified busbars to guarantee reliability and safety, making it essential to adopt best practices in busbar fabrication and production.

- High-quality aluminum materials for durability and conductivity

- Customization options for specialized designs to meet unique project requirements

- Advanced fabrication techniques for precision and efficiency

- Capability to produce busbars in various sizes and configurations

- Compliance with industry standards and certifications for safety and reliability

- Integration of innovative technologies to enhance manufacturing processes

- Commitment to sustainable practices in aluminum sourcing and production

Standard and Customized Solutions

Expert Aluminum Busbar Manufacturing for Superior Performance focuses on delivering both standard and custom solutions to meet diverse industry needs. This approach includes producing exceptional busbars that outperform traditional copper busbars. With various different busbar designs available, manufacturers can accommodate a wide range of applications. The ability to provide quick busbar design services ensures timely delivery for any busbar project, enhancing operational efficiency. Quality aluminum forms the backbone of these solutions, ensuring durability and performance under demanding conditions.

Custom busbars are particularly advantageous for projects requiring specific dimensions and configurations such as extra-large busbars or rigid busbars. By tailoring solutions to meet unique specifications, manufacturers achieve optimal quality aluminum that aligns with client requirements. The emphasis on quality throughout the manufacturing process guarantees that each product, whether standard or customized, meets the highest industry standards. This commitment to expert aluminum busbar manufacturing enhances overall performance and reliability in various applications.

Performance Characteristics of Aluminum Busbars

Expert Aluminum Busbar Manufacturing for Superior Performance ensures that aluminum busbars exhibit remarkable performance characteristics essential for various electrical busbar applications. The manufacturing process utilizes high-quality aluminum alloy to create durable busbar assemblies. These assemblies can include insulated busbars designed for enhanced safety and laminated busbars that provide improved conductivity. Massive busbar systems benefit from innovative multi-layer busbars, allowing for efficient space utilization and effective heat dissipation. The incorporation of flexible busbars and busbar shunts enhances adaptability in dynamic environments, making them suitable for a wide range of applications.

The performance of aluminum busbars is tightly linked to their structural and operational features. Expert Aluminum Busbar Manufacturing for Superior Performance emphasizes design elements that maximize current-carrying capacity while minimizing energy losses. A well-engineered busbar system ensures reliability under high-load conditions, making it ideal for industrial settings. Laminated busbars serve to reduce inductance, thereby enhancing overall efficiency in electrical systems. This careful consideration of design and material properties contributes to the exceptional performance characteristics needed in contemporary electrical busbar applications.

Modern Busbar Manufacturing Technology

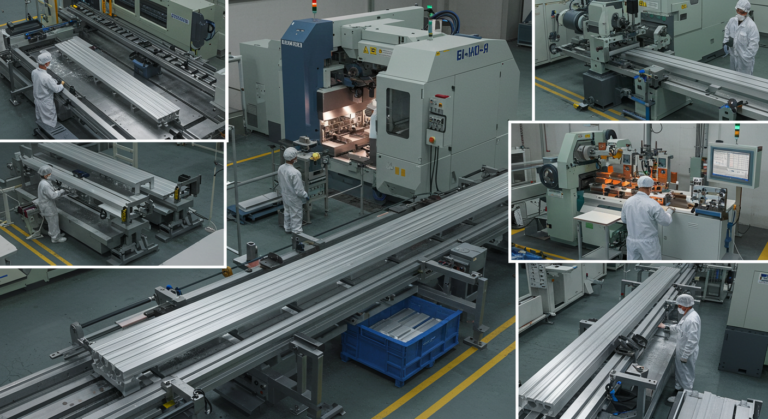

The landscape of aluminum busbar production has transformed significantly with the integration of advanced manufacturing techniques. These innovations allow for the creation of robust busbars that outperform traditional busbars in various applications. Expert aluminum busbar manufacturing for superior performance now relies on efficient manufacturing techniques that optimize the use of different grade aluminum. This results in stronger, lighter, and more reliable products. Tailored busbar solutions, complete with customizable busbar features, cater to the specific demands of industries such as energy and transportation. Battery busbar shunts exemplify the need for precision in design and functionality. The evolution towards plated busbars not only enhances conductivity but also improves resistance to environmental factors, leading to longer-lasting busbar solutions in a competitive market.

Innovations in Busbar Production

The evolution of expert aluminum busbar manufacturing for superior performance incorporates advanced manufacturing processes that significantly enhance the quality and efficiency of production. Modern techniques leverage state-of-the-art manufacturing technology to ensure precise bus bar dimensions and optimal designs. Precision manufacturing processes are essential in creating nickel-plated busbars, which improve corrosion resistance and overall functionality. This focus on quality directly influences the manufacturing process, leading to superior busbar connectors that meet stringent industry standards.

Innovations in the production of humble busbars have also focused on enhancing busbar emissivity ampacity, allowing for better heat dissipation and higher electrical performance. The integration of industrial machinery with cutting-edge technology streamlines the manufacturing processes, resulting in faster production times and reduced waste. Companies invested in expert aluminum busbar manufacturing for superior performance are now able to provide tailored solutions that meet specific application needs while ensuring reliability and durability in demanding environments.

Impact of Technology on Manufacturing Efficiency

Technological advancements have revolutionized Expert Aluminum Busbar Manufacturing for Superior Performance. Modern machinery and equipment enhance the precision manufacturing process, ensuring that bus bars meet exact specifications. The implementation of advanced machining capabilities allows for the efficient creation of components such as two-layer busbars feature, which provide improved conductivity and thermal management. This level of precision also reinforces the structural integrity of bus bars, making them compatible with industrial steel frameworks that support various applications.

The integration of cutting-edge technology in manufacturing has optimized the production of control equipment and mechanical equipment. Equipment performs with increased accuracy and speed, reducing waste and enhancing overall manufacturing efficiency. Precision metal fabrication techniques contribute to streamlined processes, allowing manufacturers to respond to changing market demands swiftly. As a result, companies that prioritize technology in their bus bar production are positioned to deliver superior performance and reliability in their products.

Benefits of Customized Aluminum Busbars

Customized aluminum busbars are essential for achieving high performance in various industrial operations. Expert aluminum busbar manufacturing for superior performance utilizes industry-leading equipment that integrates modern machinery, ensuring precise specifications. The 6063-T52 aluminum alloy is widely preferred for its excellent strength-to-weight ratio and superior conductivity. Processes such as extrusion, forging, and accurate machining processes allow for tailored solutions that enhance vehicle efficiency and overall performance. By focusing on these elements, manufacturers can deliver busbars that meet specific application needs, providing significant advantages over standard offerings.

| Benefit | Description | Application Area |

|---|---|---|

| High Conductivity | Customized aluminum busbars offer superior electrical conductivity, reducing energy loss. | Electrical Distribution Systems |

| Lightweight | Being made from aluminum, these busbars have a lower weight compared to copper alternatives, enhancing overall system efficiency. | Transportation and Automotive Industries |

| Flexibility | They can be designed according to specific dimensions and requirements, making them ideal for unique applications. | Renewable Energy Systems |

| Corrosion Resistance | Aluminum busbars resist corrosion, ensuring a longer life span and reduced maintenance costs. | Marine and Outdoor Installations |

Tailoring Solutions for Specific Applications

Customized aluminum busbars can significantly enhance the functionality of electrical equipment. Expert Aluminum Busbar Manufacturing for Superior Performance relies on advanced bar design techniques, such as our unique tin-on-aluminum process known as hyper plate. This method not only improves conductivity but also ensures that unassuming metal bars maintain a finishing capacity that meets the demanding requirements of electrical systems. Manufacturers can leverage engineering options that incorporate specific panel configurations to fit various applications, all while adhering to rigorous quality control standards.

Tailoring busbars to specific applications allows manufacturers to create optimal performance solutions that align with the needs of diverse industries. With the precision of penjing precision metal, these tailored designs ensure that each product performs efficiently, regardless of the application. Electrical equipment manufacturers benefit from customized busbars that not only match their technical specifications but also enhance the overall efficiency of their systems. By prioritizing expert aluminum busbar manufacturing, companies can achieve superior performance and reliability in their electrical configurations.

Enhancing Performance with Custom Designs

Custom designs play a crucial role in achieving optimal performance in various industrial applications. Expert aluminum busbar manufacturing for superior performance focuses on the creation of solutions tailored to specific needs. Utilizing state-of-the-art CNC machining and forming machinery, manufacturers can produce high-reliability mechanical parts that withstand the rigors of demanding environments. These durable constructions ensure that aluminum busbars meet the unique production characteristics required for high-volume production runs while delivering exceptional performance stability.

By assessing the unique needs of each industrial facility, manufacturers can create customized aluminum busbars that enhance overall efficiency. This approach not only maximizes production capabilities but also addresses specific challenges faced in the field. Custom designs facilitate improved electrical conductivity and heat dissipation, making them ideal for a range of industrial applications. Expert aluminum busbar manufacturing for superior performance derives its strength from adapting to the evolving demands of the market while maintaining the highest standards of quality and reliability.

Applications of Aluminum Busbars

Aluminum busbars are versatile components, widely utilized in various sectors such as power distribution, renewable energy, and rail transport. The essence of Expert Aluminum Busbar Manufacturing for Superior Performance lies in ensuring these busbars incorporate built-in high-reliability features and adhere to industry standards. Production capacity is vital, with designs that consider both typical design needs and advanced production methods like the tin-on-aluminum hyper plate. Effective product parts crafted from high-quality materials enhance performance while optimizing production efficiency. As manufacturers achieve automation in their processes, they create a huge setup that meets the demands of modern applications, ensuring the delivery of tailored solutions suitable for diverse operational requirements.

- Cost-effective solution for electrical connections

- High conductivity and efficiency in power transmission

- Lightweight yet strong, reducing structural load

- Corrosion-resistant properties suitable for various environments

- Easy to customize for different electrical configurations

- Supports increased energy demand in infrastructure projects

- Ideal for both indoor and outdoor installations

Conclusion

Expert Aluminum Busbar Manufacturing for Superior Performance ensures that industries benefit from high-quality busbars tailored to meet their exact specifications. The focus on precision parts like metal domes significantly enhances workability and the ability to operate under high requirements. Such attention to detail guarantees consistent performance and reliability, essential for various applications. By prioritizing quality products, manufacturers can confidently deliver solutions that align with the specific needs of their clients, reinforcing the importance of expert craftsmanship in the aluminum busbar industry.

FAQS

What are the benefits of choosing a factory that specializes in customized aluminium busbars for various industrial applications?

Choosing a factory that specializes in customized aluminium busbars offers several advantages, including the ability to meet specific busbar designs tailored to your industrial manufacturing needs. These aluminium busbar manufacturers use state-of-the-art manufacturing processes such as extrusion, forging, and machining to ensure optimal quality aluminium products. Moreover, their expertise allows for the creation of popular aluminum bus solutions that enhance the performance of bus bar components in different panels and industrial facilities, ensuring high-quality outcomes for your operating requirements.

How can I purchase high-quality aluminum busbar components online to meet specific design considerations for my project?

You can purchase high-quality aluminum busbar components online through specialized suppliers like S&S Industries. They offer a range of products including aluminum bars and bus bar bases made from 6063-T52 aluminum. Their unique tin-on-aluminum process, known as Hyper Plate, enhances performance and reliability. Make sure to consider your design considerations while selecting the right bus bar for your needs.

Where can I find high quality aluminum busbars online, particularly those using the 6063-T52 aluminum offers and the hyper plate: our unique tin-on-aluminum process?

You can purchase high quality aluminum busbar online through vendors specializing in bus bar–s+s industries, where they offer products made with 6063-T52 aluminum and utilize the hyper plate: our unique tin-on-aluminum process for superior performance.

What makes 6063-T52 aluminum offers a preferred choice for aluminum busbars in industrial applications?

The 6063-T52 aluminum offers exceptional strength and conductivity, making it an ideal material for aluminum busbars used in various industrial applications. These qualities ensure superior performance and durability in demanding environments, making 6063-T52 a widely recommended option.

How do customized aluminum busbars enhance electrical performance in demanding industrial environments?

Customized aluminum busbars are designed to meet specific electrical requirements, ensuring optimal conductivity and durability in demanding industrial environments. By tailoring the design to fit unique specifications, these busbars can effectively manage electrical loads, reduce energy loss, and withstand harsh conditions, resulting in superior performance for industrial applications.