Aluminum Busbars for High-Performance Electrical Systems

Aluminum busbars for high-performance electrical systems serve as essential components in the effective distribution of electrical power. Acting as conductive pathways, these electrical busbars facilitate the flow of electricity within various setups, from industrial applications to electric vehicle charging stations. The lightweight and corrosion-resistant properties of aluminum make these bus bars ideal for high-efficiency electrical systems. Designed to carry high current loads, aluminum busbars are integral to optimizing energy transfer within bus ducts and other electrical distributions. Their versatility ensures reliable operation across diverse applications, reinforcing the significance of choosing the right busbar for any electrical system.

Aluminum Busbars for High-Performance Electrical Systems | Definition of Electrical Busbars

Electrical busbars serve as crucial components in distributing electrical power within systems. They function as electrical conductors that facilitate the efficient transmission of electricity between different electrical installations. Aluminum busbars for high-performance electrical systems are particularly beneficial due to their lightweight properties, making them easier to handle and install. Designed to connect various electrical connectors, they are essential for both industrial applications and portable electronics, maximizing electrical efficiency and performance.

Electronics engineers often prioritize busways in their designs, particularly for electric vehicles and renewable energy solutions. The use of aluminum can enhance the thermal management of electrical systems, enabling better heat dissipation. This results in improved performance and safety in electrical and electronics applications, showcasing the versatility of aluminum busbars in high-performance electrical systems. Understanding the role of these busbars is vital for effective electrical engineering and system design.

Importance of High-Performance Electrical Systems

High-performance electrical systems are essential for optimizing the efficiency and reliability of electrical power distribution. Aluminum Busbars for High-Performance Electrical Systems play a crucial role in ensuring stable electrical energy flow throughout various applications. These busbars, often made from aluminum alloy, significantly reduce the weight compared to traditional copper conductors, facilitating easier installation and transportation. They enable improved electrical connections among components in a wide range of electronics, further enhancing performance.

The significance of high-performance electrical systems extends beyond mere efficiency. They are vital in various industries that rely on robust electrical distribution networks. Implementing Aluminum Busbars for High-Performance Electrical Systems allows designers to leverage materials like 6061 aluminum, which provides excellent conductivity and durability. This results in lower resistance and heat generation, optimizing thermal management in critical applications, including industrial setups and renewable energy solutions. Resources like aluminum.org offer further insights into the benefits of aluminum in electrical applications.

- Enhances energy efficiency by minimizing energy loss.

- Provides a lightweight alternative to traditional conductors, easing installation.

- Improves electrical connections, leading to better overall system performance.

- Reduces heat generation, contributing to safer operation in high-demand environments.

- Supports renewable energy applications by facilitating effective power distribution.

- Offers excellent durability and resistance to corrosion, increasing system longevity.

- Contributes to lower maintenance costs due to increased reliability and performance.

Advantages of Aluminum Busbars

Aluminum Busbars for High-Performance Electrical Systems are becoming increasingly essential in various sectors such as aerospace, electronics industries, and electricity distribution. Their lightweight properties significantly enhance the efficiency of wiring in high-voltage applications, offering a robust alternative to traditional copper-clad aluminum options. This shift aligns with the standards set by the Institute of Electrical and Electronics Engineers (IEEE), promoting optimal performance in machines and battery power systems. As the demand for reliable and cost-effective solutions grows, the advantages of aluminum busbars are being recognized in both industrial setups and renewable energy projects, reinforcing their critical role in modern electrical infrastructure.

Lightweight Properties of Aluminum

The lightweight properties of aluminum make it an ideal choice for applications involving energy transmission, such as aluminum busbars for high-performance electrical systems. Aluminum busbars, particularly conductive aluminum busbars, facilitate the efficient transmission of electrical power while minimizing structural load. This is especially beneficial in systems where space and weight constraints are critical, such as in industrial electrical systems or installations for electronic devices.

Aluminum extraction and recycling processes contribute to the appeal of aluminum busbars in terms of sustainability. High-quality aluminum busbars not only deliver excellent conductivity but also support environmentally-friendly practices through their recyclability. By choosing conductive aluminum busbars, industries can enhance their energy transmission systems while also aligning with green initiatives, promoting a circular economy in the production and use of aluminum busbars for high-performance electrical systems.

| Property | Value | Significance |

|---|---|---|

| Density | 2.7 g/cm³ | Lightweight, reducing overall system weight |

| Electrical Conductivity | Approximately 61% IACS | Efficient power transmission |

| Recyclability | 100% | Supports sustainability and resource conservation |

| Corrosion Resistance | High | Ensures durability and longevity in various environments |

Cost-Effectiveness and Value

The implementation of aluminum busbars in high-performance electrical systems significantly reduces material costs without compromising on functionality. Aluminum busbars are favored for their lightweight properties, making them easy to handle and install. Their affordability extends beyond the initial purchase price, as these electrical busbar products often require less structural support compared to heavier alternatives. This cost efficiency is particularly evident with custom aluminum busbars tailored to specific application needs, providing a balance of performance and value.

Choosing solid aluminum busbars or flexible aluminum busbars for high power applications brings long-term financial benefits. The durability of aluminum bus bars ensures longevity, minimizing the need for frequent replacements. In various industrial settings, aluminum busbar connections have proven effective in maximizing space while maintaining high electrical efficiency. With their capacity for customization, lightweight aluminum busbars are not only practical but also an economically sound investment for both current and future electrical systems.

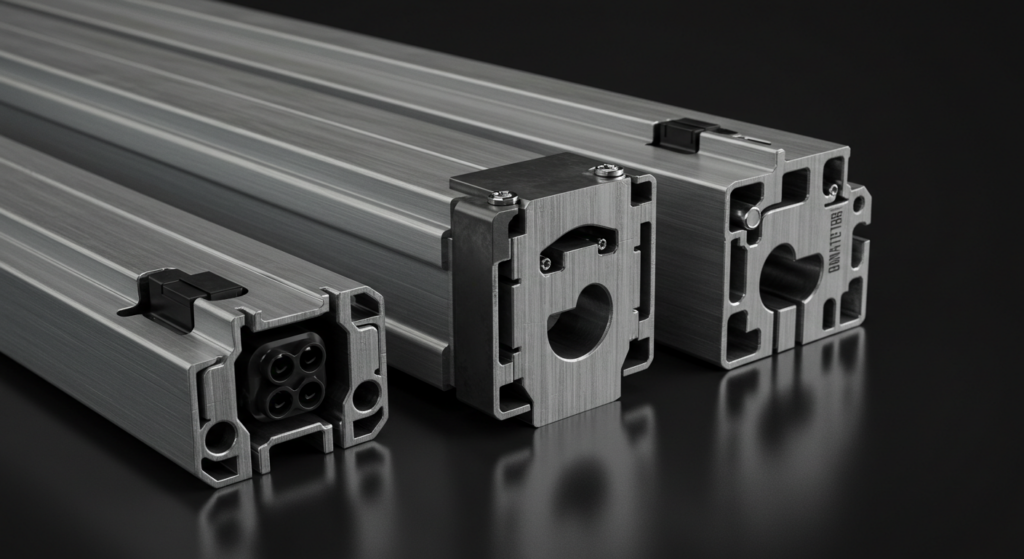

Types of Aluminum Busbars

Aluminum Busbars for High-Performance Electrical Systems come in various forms, each designed to meet specific operational needs across multiple applications. A popular choice is the store aluminum busbar, which offers durability and efficiency. Battery busbars are tailored for energy storage solutions, ensuring optimal performance in electric vehicles and renewable energy systems. Shogo aluminum busbars stand out for their advanced engineering, providing reliable connections. The versatility of custom aluminum bus options allows for adaptations in diverse busbar applications. While copper busbars are traditionally favored for high conductivity, innovations like copper-clad aluminum busbars offer a balance of weight and performance, enhancing the overall effectiveness of copper busbar manufacturing. The market also increasingly values quick quote systems for obtaining aluminum busbars, allowing users to easily assess pricing for well-engineered busbar designs that meet their specific needs.

Conductive Aluminum Busbars Explained

Conductive aluminum busbars serve a crucial role in high-performance electrical systems. Their design focuses on maximizing conductivity while minimizing weight, making them a preferred choice over traditional copper bus bars in many applications. The busbar design process takes into account key factors like current carrying capacity, thermal efficiency, and installation space. High-quality custom busbars can be engineered to meet specific system requirements, including extra-large busbars for demanding situations.

Effective busbar design considerations also include the choice of busbar material. Aluminum busbars offer significant advantages in terms of cost-effectiveness and weight compared to copper bus bars. Pre-assembled busbars streamline the installation process, allowing for quicker deployment within electric systems. The versatility of aluminum busbars for high-performance electrical systems makes them an essential component in modern electrical infrastructure.

High-Quality Aluminum Bus Options

High-quality aluminum bus options are essential for ensuring optimal performance in Aluminum Busbars for High-Performance Electrical Systems. These options often include laminated busbars that consist of multiple layers, enhancing conductivity and thermal performance. Proper busbar design is crucial for maximizing efficiency in a busbar network. Selecting the right bus bar fasteners and busbar materials will significantly impact the overall functionality and durability of the system, making informed choices a key consideration for successful installation.

The variety of busbar products available includes single-layer busbars and laminated designs tailored for specific applications. Busbar considerations such as electrical load, environmental conditions, and installation space play a pivotal role in determining the best busbar solutions. By understanding the differences between these options, users can select the most suitable aluminum busbars for high-performance electrical systems, ultimately ensuring reliability and longevity in their applications.

Applications of Aluminum Busbars

Aluminum busbars for high-performance electrical systems are pivotal in various applications, including industrial electrical setups and renewable energy projects. The right busbar material ensures efficient power distribution and is essential for creating custom busbars tailored to specific operational needs. Custom busbar design allows for the integration of long busbar lengths and bus bar connectors, optimizing space and performance in bus systems. Tailor-made aluminum buses not only enhance reliability but also ensure seamless connectivity within electrical networks. Selecting the appropriate bus bar design maximizes efficiency while accommodating diverse operational demands.

Use in Industrial Electrical Systems

Aluminum Busbars for High-Performance Electrical Systems are vital in industrial electrical setups, providing reliable connections and efficient power distribution. Utilizing aluminum conductors, these custom busbar solutions are tailored to meet specific requirements for each application. Key busbar considerations include current carrying capacity and thermal management, ensuring that the system operates at optimal efficiency. Projects often benefit from the incorporation of aluminum connectors that enhance the overall electrical system performance.

The integration of chalco copper busbars can further elevate the effectiveness of industrial electrical systems. By understanding custom busbar requirements, engineers can design and implement a custom busbar that meets the needs of their next busbar project. This attention to detail ensures that each critical bus bar functions effectively, delivering the necessary reliability and performance expected in demanding environments. Aluminum Busbars for High-Performance Electrical Systems are essential components that help maintain energy efficiency and system integrity.

Role in Renewable Energy Solutions

Aluminum busbars play a crucial role in renewable energy solutions, where efficiency and reliability are paramount. These components, especially when custom-designed as thicker bus bars, enhance electrical performance in high-power applications such as solar and wind energy systems. High conductivity aluminum provides an ideal solution for conducting electricity effectively, and the use of laminated busbarsquick ensures minimal energy loss. Implementing the correct bus bar type is essential for optimizing system performance in renewable energy installations.

The integration of conductive bus technology in renewable systems provides advantages in both setup and maintenance. Aluminum busbars for high-performance electrical systems serve as vital bus connectors that facilitate seamless energy distribution. These aluminum bars are often engineered specifically for each project, ensuring compatibility with the demands of renewable energy infrastructures. As more companies focus on sustainable solutions, the demand for reliable, efficient busbarsquick continues to rise, underscoring the importance of advanced designs in the industry.

Evaluating Aluminum Busbar Capabilities

Aluminum Busbars for High-Performance Electrical Systems play a crucial role in enhancing the reliability and efficiency of electrical infrastructure. These bus solutions are particularly effective in high-current applications, where the aluminum core conducts electricity with minimal resistance. The lightweight properties of aluminum offers significant advantages over traditional copper options, making it ideal for use in busway systems that support heavy electrical equipment. With the rising demand for electric vehicle production and the development of robust electrical systems, selecting the appropriate aluminum busbars ensures optimal current carrying capacity and thermal management. This directly impacts the overall performance and longevity of electrical equipment, solidifying aluminum’s position as a preferred choice in modern electrical installations.

- Aluminum busbars are cost-effective compared to copper alternatives.

- They offer superior corrosion resistance, extending their lifespan in diverse environments.

- Lightweight design simplifies installation and reduces structural support requirements.

- High conductivity ensures efficient energy transfer and minimizes energy loss.

- Aluminum busbars can be easily customized to meet specific application needs.

- Their thermal conductivity aids in heat dissipation, promoting safe operation.

- Compliance with industry standards ensures reliability in critical applications.

Current Carrying Capacity and Ratings

The current carrying capacity of aluminum busbars is a critical factor that dictates their performance in high-performance electrical installations. These buses are engineered to support various electrical applications, ensuring efficient energy distribution across systems. Proper ratings allow for the safe and reliable conductance of electricity through devices and components. Aluminum busbars for high-performance electrical systems are designed to meet the demands of modern electrical distribution systems, with efficiency and safety at the forefront of their design.

Understanding how aluminum differs from other materials in terms of current ratings is essential for selecting the right busbar for specific applications. Aluminum fabrication delivers a lightweight solution that does not compromise strength or efficiency, making it ideal for energy storage equipment and other electrical devices. Choosing to install aluminum busbars over heavier alternatives can lead to more streamlined setups and effective high-efficiency systems. Such thoughtful integration ensures that electrical installations operate at optimal levels while meeting the rigorous demands of contemporary electrical infrastructure.

Thermal Management and Efficiency

Effective thermal management is crucial for Aluminum Busbars for High-Performance Electrical Systems. Utilizing materials like aa6063 aluminum enhances conductivity and helps dissipate heat efficiently. This characteristic is vital in high-load capacity applications, such as power distribution panels and battery power systems. The ability to maintain lower temperatures directly influences the performance and longevity of aluminum products. Proper aluminum fabrication techniques can further optimize performance hinges, ensuring minimal heat build-up during high-power operations.

Ensuring optimal thermal efficiency in aluminum busbars directly impacts their current carrying capacity. High-performance scenarios demand busbars that can handle higher electrical loads without compromising safety. Implementing advanced cooling strategies such as thermal insulation or airflow optimization can lead to better performance in clean energy applications. The combination of these elements not only maintains efficiency but also supports long-term reliability in applications like cca bus configurations, reinforcing the importance of thermal management in these systems.

Installation Considerations for Aluminum Busbars

Proper installation of Aluminum Busbars for High-Performance Electrical Systems is crucial to meet electrical requirements in various applications. These busbars, crafted from lightweight metal, facilitate efficient performance in high-voltage applications, addressing the significant electrical demands of a battery power system. Utilizing custom aluminum configurations can optimize space and functionality, especially in electric vehicle drive setups and industrial power applications. Round angle aluminum designs enhance connection reliability while ensuring safety and compliance. Careful consideration of installation best practices not only reduces transportation challenges but also maximizes the efficiency and longevity of the electrical device in which they are utilized.

Best Practices for Setup

Proper installation of aluminum busbars is crucial for ensuring optimal performance in safety-critical applications. Using high-quality components, such as 6063-T52 aluminum, helps guarantee structural integrity and reliability in critical power applications. Correct alignment and secure mounting of the busbars contribute to a stable overall power system. It is vital to ensure that connections are tight and that the busbars are appropriately rated for the specific electrical project. This attention to detail enhances functionality across a wide range of applications, from utility-scale power systems to smaller electrical panels.

Careful planning and execution during setup significantly impact the longevity and efficiency of aluminum busbars. The placement of these busbars should consider thermal expansion and airflow to prevent overheating of equipment. Proper sizing and spacing of the busbars are essential to facilitate adequate current distribution and minimize losses. Regular inspections will maintain their performance over time, making them a preferred choice in high-performance electrical systems. Employing these best practices ensures that aluminum busbars deliver reliable service and uphold safety standards across various industrial applications.

| Best Practice | Description | Benefits |

|---|---|---|

| Use High-Quality Materials | Opt for 6063-T52 aluminum for enhanced structural integrity. | Improved reliability in critical power applications. |

| Ensure Correct Alignment | Align busbars accurately during installation. | Prevents mechanical stress and enhances performance. |

| Secure Mounting | Use appropriate mounting hardware to secure busbars. | Increases stability and reduces risk of disconnection. |

| Regular Inspections | Conduct periodic evaluations of busbars and connections. | Enhances longevity and maintains performance efficiency. |

Common Mistakes to Avoid

Proper installation of Aluminum Busbars for High-Performance Electrical Systems is crucial to avoid common pitfalls that can lead to inefficiencies. Failing to account for the load-bearing capacity can result in inadequate support for conductors, affecting the overall performance of power systems. It’s vital to ensure that distribution panels are designed to meet high ampacity requirements to facilitate efficient energy transmission. Neglecting these factors can lead to overheating and eventual system failure, particularly in high-current scenarios.

Another frequent mistake lies in overlooking the maintenance needs of systems utilizing Aluminum Busbars. Regular checks and upkeep are essential to ensure optimal functionality, especially in applications involving new energy systems and machines. Allowing dirt or corrosion to build up can hinder good power distribution, impacting the overall efficiency of many applications. Proper attention to these aspects can significantly extend the lifespan and reliability of Aluminum Busbars for High-Performance Electrical Systems.

Conclusion

Aluminum Busbars for High-Performance Electrical Systems serve as essential components that enhance the efficiency and reliability of electrical networks. These robust conductors, often designed as rectangular pieces, facilitate seamless connections between various cables, optimizing power distribution. Their lightweight and durable nature makes them an ideal choice for demanding environments, ensuring reduced installation costs and improved performance. The increased adoption of Aluminum Busbars for High-Performance Electrical Systems is a testament to their significant role in modern electrical infrastructure, particularly within industrial applications and renewable energy solutions.

FAQS

What are the benefits of using aluminum bus bars in high-performance electrical systems?

Aluminum bus bars offer several advantages in electrical systems, including high load capacity and electrical system reliability. These components are optimized for optimal performance, especially in high power busbar applications. Additionally, the usage of copper clad aluminum and laminated busbars consist of materials that enhance conductivity, making them ideal for custom busbar projects. Aluminum conducts electricity efficiently, and hot selling aluminum options like 6063-T52 aluminum offers wide applications that suit various electrical components. For those seeking a quick quote for busbars, aluminum busbars are a popular choice due to their blend of performance and cost-effectiveness.

How does aluminum recycling contribute to the efficiency of aluminum busbars in electrical systems?

Aluminum recycling is essential because it allows for the creation of custom bus bars that meet specific performance requirements. By using recycled aluminum, manufacturers can ensure their bus bar material is both sustainable and cost-effective. Additionally, copper-clad aluminum busbars combine the benefits of both metals, ensuring optimal performance hinges on the quality of materials used. Quick quotes for these aluminum busbars can be obtained, and their rectangular conductors provide enhanced efficiency in high-performance electrical systems.

How can copper-clad aluminum busbars improve efficiency in high-performance electrical systems?

Copper-clad aluminum busbars provide an excellent solution for enhancing efficiency in high-performance electrical systems. These busbars combine the lightweight properties of aluminum with the conductivity of copper, which allows for quicker response times. If you’re interested in a quick quote for copper-clad aluminum busbars, our team can assist you to ensure that your busbars meet the specifications needed for your projects.

What makes copper-clad aluminum busbars a preferred choice for improving efficiency in high-performance electrical systems?

Copper-clad aluminum busbars are often preferred in high-performance electrical systems because they provide a balance of conductivity and weight. These busbars can facilitate a quicker installation process due to their lightweight nature, which is critical for ensuring that the busbar meets the performance demands of modern applications. Additionally, you can easily obtain a quick quote for custom aluminum busbars tailored to specific needs, ensuring efficient system performance.

How can I obtain a quick quote for copper-clad aluminum busbars to enhance my high-performance electrical systems?

You can obtain a quick quote for copper-clad aluminum busbars by contacting suppliers who specialize in aluminum busbars. Many companies offer quick quote services for busbars, including copper-clad options, to help you evaluate costs and improve efficiency in your high-performance electrical systems.

How do I request a quick quote for aluminum busbars or copper-clad aluminum busbars to enhance my electrical systems?

To obtain a quick quote for aluminum busbars or copper-clad aluminum busbars, you can visit our website and fill out the request form, or contact our sales team directly via email or phone. Our team will assist you promptly with personalized quotes for your high-performance electrical systems.

What is the process to request a quick quote for aluminum busbars or copper-clad aluminum busbars?

To request a quick quote for aluminum busbars or copper-clad aluminum busbars, visit our website or contact our sales team directly via email or phone. We provide a user-friendly form that enables you to specify your needs and receive your quick quote promptly. Our team is dedicated to enhancing your electrical systems with our high-quality busbars, ensuring you get the information you need quickly.

How can I efficiently request a quick quote for copper-clad aluminum busbars in order to upgrade my electrical systems featuring aluminum busbars?

To efficiently request a quick quote for copper-clad aluminum busbars, you can visit our website or contact our sales team directly, ensuring to specify the aluminum busbars you are interested in. We’re here to assist you with a quick quote for both aluminum busbars and copper-clad aluminum busbars to enhance your electrical systems.

What steps should I follow to receive a quick quote for both aluminum busbars and copper-clad aluminum busbars for my electrical systems?

To receive a quick quote for aluminum busbars and copper-clad aluminum busbars, start by contacting the supplier through their website or customer service. Provide details about your requirements, including specifications and quantities, which will help them offer you a fast and accurate quote. Using this approach ensures that you can quickly get the information needed to make informed decisions about your electrical systems.

What is the best way to get a quick quote for copper-clad aluminum busbars and aluminum busbars to optimize my electrical systems?

To receive a quick quote for copper-clad aluminum busbars and aluminum busbars, you should contact a reputable supplier who specializes in busbars. Ensure to provide details about your electrical systems as this will help in obtaining an accurate and quick quote for your needs.