Aluminum Busbars | Lightweight & Efficient Power Conductors

Aluminum busbars serve as lightweight and efficient power conductors, providing a crucial role in distributing electrical loads across various systems. These busbars are designed to conduct electricity with minimal resistance, making them a popular choice in many applications. Featuring a robust configuration, aluminum conductors excel in both industrial and commercial settings, where reliability and performance are paramount. The use of bus bars enables streamlined connections between electrical conductors, enhancing the overall efficiency of electrical systems. Understanding the characteristics and advantages of aluminum busbars is essential for optimizing their implementation in different applications of aluminum, ultimately supporting effective energy management.

- Aluminum busbars offer significant weight savings compared to copper alternatives.

- They provide excellent thermal conductivity, helping to dissipate heat effectively.

- Corrosion-resistant properties enhance their longevity and reliability.

- Aluminum busbars are cost-effective, making them suitable for budget-conscious projects.

- Their modular design allows for easy installation and flexibility in system configurations.

- They can be used in renewable energy systems, such as solar and wind power installations.

- Aluminum busbars are commonly employed in switchgear, transformers, and power distribution systems.

Aluminum Busbars | Lightweight & Efficient Power Conductors | Definition and Purpose of Aluminum Busbars

Aluminum busbars serve as crucial components designed to conduct electrical loads efficiently. These lightweight and efficient power conductors are commonly used in various applications, including bus ducts and electrical panels. Constructed from aluminum alloys, they provide superior conductivity compared to heavier materials like steel. Their inherent properties make them suitable for overhead power lines and systems that require reliable performance under demanding conditions, such as powering heavy machinery.

The primary purpose of aluminum busbars is to facilitate the distribution of electricity within industrial and commercial settings. Their design allows for streamlined connections between various electrical components while minimizing energy loss. Anodized aluminum finishes enhance durability and resistance to corrosion, ensuring longevity in harsh environments. The flexibility of aluminum allows for easier installation and maintenance, making aluminum busbars a preferred choice in many electrical infrastructure projects.

Key Characteristics of Aluminum Busbars

Aluminum Busbars are known for their robust characteristics that make them ideal for various applications. As lightweight & efficient power conductors, they outperform traditional metal options like stainless steel in many scenarios. The use of aluminum alloy enhances their ability to handle electrical power without compromising structural integrity. Electronics engineers favor these busbars due to their excellent conductivity and reduced weight, which allows for easier installation and handling in busways for electrical and electronics systems.

Another notable characteristic of Aluminum Busbars is their resistance to corrosion, largely due to aluminum oxide formation on the surface. This natural protective layer extends the lifespan of these conductors in demanding environments. Not only do these busbars provide superior electrical conductivity, but they also contribute to energy efficiency in electrical systems. Their versatile design accommodates various installations, making them a preferred choice for numerous electrical applications.

Advantages of Aluminum Busbars

Aluminum Busbars | Lightweight & Efficient Power Conductors offer significant advantages in various applications, particularly due to their lightweight nature and efficient conductivity. These characteristics make them ideal for integration into portable electronics and electric vehicles, where saving weight without compromising performance is crucial. In transportation and industrial machines, the robust design of aluminum busbars supports the structural load while efficiently transferring electric power through electrical connectors. The efficiency of aluminum busbars also extends to electrical power systems, reducing energy losses compared to traditional wires. The aluminum recycling process enhances their sustainability, promoting eco-friendly practices within the industry and fostering a cycle that includes aluminum extraction. The overall benefits of aluminum busbars position them as essential components in modern electrical infrastructure.

- Lightweight design reduces overall weight in applications like electric vehicles.

- High conductivity ensures efficient power transfer, minimizing energy losses.

- Robust construction supports significant structural loads effectively.

- Corrosion resistance increases longevity, reducing maintenance costs.

- Cost-effective compared to copper alternatives, making them budget-friendly.

- Environmentally sustainable due to the recyclability of aluminum.

- Versatile applications in various industries, including transportation and power systems.

Lightweight Nature of Aluminum Busbars

Aluminum busbars serve as central conductors in various electrical systems, providing significant weight advantages over traditional copper alternatives. Their lightweight nature makes them ideal for electrical installations, particularly in large electrical panels and electric power systems where space and weight constraints are crucial. Modern aluminum busbars, known for being lightweight & efficient power conductors, facilitate streamlined electrical power distribution while minimizing structural burden and enhancing overall efficiency in design.

The reduced weight of aluminum busbars enables easier handling and installation, which can significantly expedite project timelines. This characteristic not only contributes to simpler setup processes but also allows for the effective integration of busbar trunking conductors with existing cables and other components in electrical systems. As a result, aluminum busbars become essential elements in the development of efficient and effective electrical infrastructures across various applications.

Efficiency in Power Conductivity

Aluminum busbars represent a significant advancement in power distribution due to their lightweight and efficient power conductor properties. With advanced aluminum busbars, systems experience improved efficiency and power density compared to traditional copper options. High-quality aluminum busbars are designed to optimize electrical conduction, making them suitable for various applications. As the demand for reliable power distribution continues to grow, aluminum busbar systems emerge as a preferred solution among engineers and designers.

The ability of aluminum ultra-conductors to improve efficiency raises their appeal in modern electrical infrastructure. Custom aluminum busbars can be tailored to meet specific operational requirements, accommodating varying load conditions and installation spaces. State-of-the-art aluminum busbars are strategically positioned within systems to enhance conductivity and reduce energy losses. This ensures that these lightweight and efficient power conductors are not only effective but also contribute to a more sustainable energy framework.

Applications of Aluminum Busbars

Aluminum busbars serve as lightweight and efficient power conductors in a variety of applications, including industrial and commercial sectors. Their high-current aluminum bus designs ensure optimal conductivity, making top-tier aluminum busbars essential for electrical panels and switchgear. These aluminum bus bars are vital for distributing power reliably and efficiently. The versatility of aluminum ultra-conductors positions them as a preferred choice over stainless steel busbars, particularly when considering weight and efficiency. Meeting specific aluminum busbar needs is crucial for achieving reliable electrical performance in any setup. Whether in high-demand industrial environments or commercial installations, the role of aluminum busbars as lightweight and efficient power conductors cannot be overstated.

| Application | Industry | Benefits |

|---|---|---|

| Electrical Panels | Commercial | High conductivity for efficient power distribution |

| Switchgear | Industrial | Lightweight design reduces installation complexity |

| Renewable Energy Systems | Energy | Supports efficient energy transfer in solar and wind technology |

| Data Centers | Technology | Reliable power distribution to critical systems |

| Manufacturing Facilities | Manufacturing | Enhances operational efficiency with reduced weight |

Industrial Uses of Aluminum Busbars

Aluminum busbars serve a vital role in various industrial applications, acting as lightweight and efficient power conductors. These high-quality aluminum bus products possess superior conductivity, making them ideal alternatives to copper busbars. Industries benefit from the lower cost of aluminum conductors, as they are more affordable than copper varieties. The shape of aluminum ultra-conductors allows for optimal busbar performance in high-load environments, ensuring reliable distribution of electrical power.

Many manufacturers are incorporating aluminum bus solutions into their operations due to their versatility and cost efficiency. From power generation facilities to manufacturing plants, high-quality aluminum busbars are essential for maintaining electrical efficiency. The use of top-quality aluminum bus materials enhances overall system reliability while reducing installation weight. By leveraging aluminum bus products, businesses can achieve robust, long-lasting solutions to their electrical distribution needs.

Commercial Applications of Aluminum Busbars

Aluminum busbars serve a crucial role in various commercial settings, offering lightweight and efficient power conductors that align with modern energy demands. High-quality busbars such as flat aluminum bus options and flexible busbars are commonly utilized in large-scale electrical distribution systems. These precision-engineered busbars efficiently manage electrical loads in commercial buildings, ensuring optimal performance. Advanced busbars, including ultra-conductors and combination busbars, are vital for creating integrated busbar systems that support complex electrical architectures.

The adaptability of aluminum busbars makes them particularly suitable for installation in both new constructions and retrofit projects within commercial environments. With efficient busbar options available, businesses can benefit from reduced energy losses and enhanced conductivity. Modern busbar systems designed with these lightweight and efficient power conductors contribute to better energy efficiency and reliability in commercial applications, catering to the unique demands of contemporary electrical infrastructures.

Design Considerations for Aluminum Busbars

Considering the design of Aluminum Busbars | Lightweight & Efficient Power Conductors is crucial for optimizing their performance in various applications. Selecting the right busbar material, whether opting for aluminum or copper bus bars, significantly impacts conductivity and efficiency. Aluminum busbars offer a lightweight nature while maintaining excellent conductivity, making them ideal for commercial conductors. Incorporating insulated bus bars prevents electrical leakage, while high-quality busbar products ensure durability and reliability. For specific needs, high-quality busbar options may include copper-aluminum bimetallic bus configurations, which combine the strengths of both materials. Lastly, choosing corrosion-resistant aluminum bus options enhances longevity, especially in harsh environments, ensuring that aluminum connectors and conductive bus bars deliver sustained performance over time.

Sizing and Ampacity Factors

Proper sizing and ampacity factors are crucial for the effective use of Aluminum Busbars | Lightweight & Efficient Power Conductors. The dimensions of aluminum bars directly impact their current-carrying capacity. Thicker bus bars can handle higher currents, making them suitable for demanding applications. Precision-engineered bus bars are designed to facilitate optimal performance, particularly in laminated busbar systems. Evaluating these factors ensures the selection of the right bus bar material for specific electrical needs, such as using nickel bus bars for enhanced conductivity.

Long busbar lengths and the choice of primary conductors must be balanced to mitigate losses and ensure efficient operation. Galvanized busbars can be effective in preventing corrosion, especially in industrial settings. It is essential to consider the ampacity ratings according to the specific requirements of next busbar projects. Understanding the central conductors’ configuration also aids in achieving maximum efficiency and safety in electrical systems utilizing Aluminum Busbars | Lightweight & Efficient Power Conductors.

Insulation and Protection Options

Effective insulation is crucial for Aluminum Busbars | Lightweight & Efficient Power Conductors, as it enhances safety and performance in various bus bar applications. High-quality bus bars often use robust busbar ducts made from durable materials to provide protection against environmental factors. Customized busbars can feature thicker bus bars for added insulation, ensuring reliability during operation. Bus bar connectors also require careful consideration to maintain insulation integrity, as poor connections can lead to overheating or failure.

Protection options for aluminum busbars include the application of composite bus bars that enhance durability while reducing weight. A reputable bus bar manufacturer offers a range of solutions tailored to specific needs, ensuring that chosen busbars meet industry standards. Employing reliable bus bars equipped with proper insulation helps minimize losses in conductivity, thereby maximizing efficiency. Investing in the right insulation and protection measures will contribute to the longevity of aluminum bars in various applications.

| Insulation Material | Thermal Conductivity (W/m·K) | Voltage Rating (kV) | Applications |

|---|---|---|---|

| Polyethylene (PE) | 0.6 | 15 | Low-voltage busbars |

| Epoxy Resin | 0.2 | 30 | Medium to high-voltage applications |

| Silicone Rubber | 0.1 | 20 | Indoor and outdoor environments |

| Fiberglass Reinforced Plastic (FRP) | 0.3 | 25 | Heavy-duty installations |

Manufacturing and Quality Standards

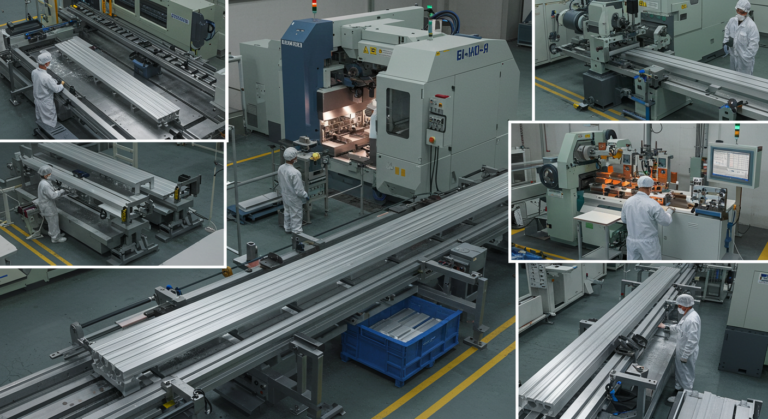

The production of Aluminum Busbars | Lightweight & Efficient Power Conductors involves several essential processes that ensure their integrity and performance. Techniques like cold forming and extrusion are commonly utilized to create bus bars with optimal dimensions and conductivity. Quality control measures are essential during manufacturing to guarantee that each bus bar meets industry standards for strength and efficiency. The use of bus bar fasteners and holders ensures secure connections within electrical busway systems, enhancing the reliability of aluminum conducts. Laminated bus bars are becoming increasingly popular due to their enhanced performance characteristics, which leverage bus bar technology to improve conductivity while reducing weight. Adhering to stringent certification and compliance standards further maximizes the busbar benefits, ensuring that these components perform effectively within various bus bar systems.

Processes Involved in Aluminum Busbar Production

The production of aluminum busbars involves several crucial processes that ensure their effectiveness as lightweight and efficient power conductors. Initially, high-strength aluminum alloys are selected to withstand various electrical load demands. Each busbar is shaped and formed through methods such as extrusion or stamping, which helps achieve both structural integrity and the desired conductivity. Once formed, the bus systems can be laminated to enhance their performance, particularly for long-span bus applications. The use of high-quality aluminum offers significant advantages compared to traditional copper bus conductors, making aluminum a preferred choice in many industries.

After shaping, the finishing processes play an essential role in ensuring the durability and reliability of aluminum busbars. Surface treatments may include anodizing or coating, which provide insulation and protection against environmental factors. These processes are critical for maintaining the integrity of the busbars in various applications where high-performance cables are utilized. The emergence of new energy aluminum technologies has further propelled the development of aluminum busbars, allowing manufacturers to produce highly efficient and robust components tailored to modern energy systems. This attention to detail in production underscores aluminum’s ability to achieve optimal performance in demanding electrical environments.

Certification and Compliance Standards

Certification and compliance standards play a crucial role in ensuring the reliability and safety of aluminum busbars as lightweight and efficient power conductors. These standards govern the manufacturing processes and materials used to produce bus bar products, ensuring they meet specific criteria for performance and safety. The high-strength aluminum composition utilized in these products allows them to handle high-power applications effectively. Compliance with relevant electrical codes and guidelines further enhances their suitability for a variety of electrical conductor applications.

Regular certification processes ensure that aluminum busbars, including flat bus bars and various bus duct solutions, maintain high quality throughout their lifecycle. Adhering to these standards guarantees that bus duct products perform optimally under different conditions and resist wear over time. By utilizing high-quality aluminum materials, manufacturers can enhance the longevity and efficiency of these components, making them an ideal choice for diverse industrial and commercial settings.

Installation and Maintenance of Aluminum Busbars

Proper installation and maintenance of Aluminum Busbars | Lightweight & Efficient Power Conductors are vital for ensuring their optimal performance in various applications. The aluminum fabrication process allows for the creation of custom bus bar dimensions tailored to specific needs, making them suitable for heavy machinery operations as well as standard electrical applications. Selecting the correct bus bar is essential, especially when dealing with high loads, as the difference in aluminum-based materials can significantly affect efficiency and safety. Implementing a customizable bus duct can further enhance functionality, ensuring that these lightweight and efficient power conductors perform effectively throughout their lifespan. Regular maintenance checks are necessary to uphold their integrity and reliability in diverse environments.

Best Practices for Installation

Proper installation of aluminum busbars significantly enhances their role as lightweight and efficient power conductors in various electrical infrastructures. Technical teams should prioritize the use of high-quality aluminum alloys to ensure optimal electrical performance. Choosing aluminum over traditional bulky wiring not only improves efficiency but also contributes to space-saving designs, especially in battery enclosures. Careful attention to the connection points and securing methods is essential to prevent any potential overheating or failures.

To maximize the benefits of aluminum solutions, attention to detail during installation is critical. Ensuring clean and secure contact between the aluminum busbars and other conductor materials will lead to better conductivity and longevity. Utilizing rhi busbars designed specifically for high-load applications can further enhance the cost-effectiveness of the overall system. Choosing the right insulation and protection options alongside proper installation techniques will prevent damage and maintain the integrity of aluminum busbars in demanding environments.

Maintenance Tips for Longevity

Regular inspections of Aluminum Busbars | Lightweight & Efficient Power Conductors are crucial for maintaining their functionality over time. Check for any signs of corrosion or damage, especially around connections and metal frames. Keeping the metal surfaces clean helps to ensure optimal conductivity. If busbars are part of high-performance applications, such as in electrical control panels or high-voltage equipment, a more frequent maintenance schedule may be necessary to prevent potential failures in the electrical infrastructure.

Selecting high-quality aluminum alloy for replacement parts can extend the life of existing busbars. The use of custom aluminum solutions tailored to specific industrial equipment needs enhances durability and reliability. Properly securing Aluminum Busbars to metal frames can also mitigate movement and vibration, reducing wear and tear. Implement preventative measures to safeguard these lightweight and efficient power conductors, ensuring they continue to provide reliable bus solutions.

Conclusion

Aluminum busbars serve as lightweight and efficient power conductors, known for their optimal load-bearing capacity in various electrical applications. These components are essential in power distribution panels, where they facilitate the safe and reliable transfer of electricity. The use of aluminum busbars enhances overall system efficiency, making them a preferred choice in both industrial and commercial sectors. Their ability to withstand high electrical loads while maintaining a lightweight profile emphasizes their importance in modern infrastructure design and power management solutions.

FAQS

What are the benefits of using aluminum busbars in electrical panels and switchgear?

Aluminum busbars are vital in electrical panels and switchgear due to their excellent conductivity and cost-effectiveness. Aluminum conductors are more affordable than copper varieties, making them a reliable option for electrical busbars. Moreover, aluminum ultra-conductors can improve efficiency and power density, while high-quality busbar materials ensure durability. Choosing aluminum can also lead to incorporating aluminum bus configurations that optimize bus bar size and shape for better performance. The elevated role aluminum plays in energy management highlights its crucial role in modern electrical systems.

How do aluminum busbars differ from other electrical conductors in terms of their applications and effectiveness in electrical systems?

Aluminum busbars serve as central conductors in various electrical systems, primarily due to their reliability and cost-effectiveness. Unlike other conductive materials, aluminum achieves a unique combination of lightweight properties and electrical efficiency, making aluminum busbars suitable for numerous applications. They play a crucial role in electrical panels and switchgear, as well as in busbar troughs, where their shape allows for optimal positioning. By incorporating aluminum bus, manufacturers can deliver exceptional electrical metal products that meet industry standards.

In what ways do aluminum bus bars serve as central conductors in various electrical applications and systems?

Aluminum bus bars serve as central conductors in electrical panels and switchgear due to their unique properties. These aluminum bus bars are vital in electrical systems because they efficiently conduct electricity while being lightweight. In positions where space is limited, choosing aluminum bus bars can enhance cost-effectiveness, as aluminum tends to be more affordable than copper alternatives. With reliable aluminum bus options available, incorporating aluminum bus in electrical designs is crucial for performance and durability. Moreover, advanced aluminum fabrication delivers tailored solutions for specific electrical needs, showcasing the versatility of aluminum materials in the industry.

Why should we choose aluminum for electrical bus bars in terms of shape and material efficiency?

Choosing aluminum busbars is essential due to their shape and aluminum ultra-conductors properties, which ensure excellent conductivity and lightweight solutions. Aluminum bus bars are vital in electrical panels and switchgear because of their cost-effectiveness and the ability to incorporate aluminum bus in various designs. Additionally, aluminum differ from other materials, making them a preferred choice for modern electrical systems.

What makes aluminum busbars suitable for different positions in electrical systems?

Aluminum busbars play a crucial role in electrical systems due to their lightweight properties and effective conductivity. When you choose aluminum for your electrical bus bars, you’re benefiting from cost-effectiveness and the ability to design them in various shapes, such as shape aluminum ultra-conductors. Additionally, aluminum materials used in busbar holders enhance the overall efficiency of the system, making aluminum busbars a highly suitable option for various positions in electrical applications.

What features of aluminum busbars contribute to their suitability for various positions within electrical systems?

Aluminum busbars are crucial for providing efficient electrical conduction across different positions in electrical systems. Their lightweight nature and cost-effectiveness make aluminum an attractive choice compared to other materials. Due to the unique properties of aluminium, such as high conductivity and resistance to corrosion, aluminium bus bars offer reliable performance in various applications, ensuring that they remain suitable for a wide range of functional scenarios.

How are aluminum busbars suitable for different positions in electrical systems and what crucial role do aluminum materials play in this context?

Aluminum busbars are suitable for various positions in electrical systems due to their lightweight properties and excellent conductivity. They play a crucial role in optimizing space and weight distribution, allowing for efficient installation in tight spaces. The use of aluminum materials in busbars enhances their effectiveness in providing reliable electrical connections across different configurations and applications.

How are aluminum busbars suitable for different positions in electrical systems and why is the crucial role aluminum plays important?

Aluminum busbars are suitable for various positions in electrical systems due to their lightweight nature and high conductivity. The crucial role aluminum plays in this context is enhanced by its ability to efficiently carry electrical currents while being easy to install in different configurations. Additionally, aluminum materials provide significant cost savings and energy efficiency, making them a preferred choice in the design of electrical conductor systems.

How do different electrical systems determine the positions where an aluminum busbar is suitable, and what role do aluminum materials play in this determination?

The determination of positions where an aluminum busbar is suitable in different electrical systems is influenced by factors such as thermal performance, conductivity, and mechanical strength. Aluminum materials are lightweight yet provide excellent conductivity, making them ideal for various positions in these systems. The efficiency and reliability of aluminum busbars in managing power distribution underscore their critical role across diverse applications.

How can the integration of aluminum busbars enhance their suitability in various electrical system positions, and what significance do aluminum materials hold in this context?

The integration of aluminum busbars enhances their suitability across various electrical system positions due to their lightweight and efficient conductive properties. Aluminum busbars are versatile and can be tailored to fit specific positions in electrical configurations, making them highly adaptable. Furthermore, aluminum materials play a significant role in determining performance and efficiency, ensuring optimal electrical flow in diverse applications.