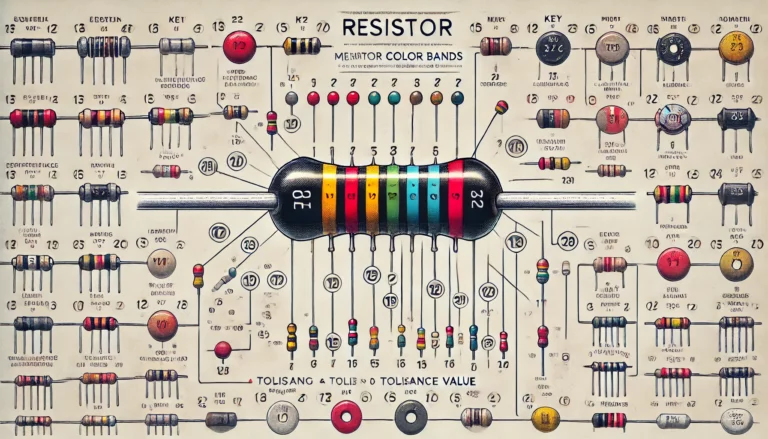

Electrical Color Bands

Different Types of Resistors

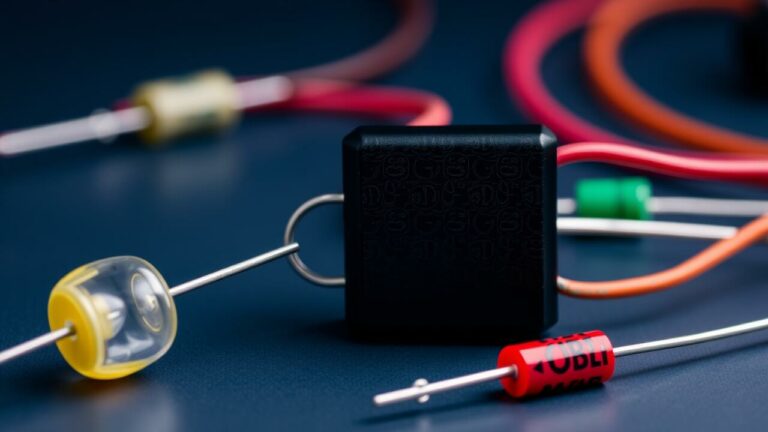

Resistors—those unsung heroes of electrical circuits—play a pivotal role, deftly regulating current flow and weaving themselves into the fabric of feedback mechanisms across countless applications. Picture this: three main contenders in the resistor arena, each boasting its unique flair. First up is the carbon film resistor, which elegantly employs a layer of carbon atop an insulating substrate; it’s known for its commendable temperature stability and admirable noise characteristics. Then we have the metal film resistors, precision aficionados that they are! With their sleek thin layers of metal foil, they bring forth lower noise levels and tighter tolerances—a perfect match for those high-stakes scenarios where accuracy reigns supreme. And let’s not forget wirewound resistors; these heavyweights consist of coils of wire wrapped around sturdy cores, equipped to tackle high power demands while excelling at heat dissipation.

Fast forward to recent years: innovation has sparked a revolution in resistor design—performance skyrockets alongside reliability! Today’s modern marvels boast materials and manufacturing techniques that bolster durability and shrink their environmental footprint. Sure, traditional resistors still hold sway over the market’s landscape, but enter stage right—the versatile surface mount resistors! Compact yet efficient, these darlings thrive in tight spaces where conventional components might falter. As our appetite for electronic devices surges ever higher, it’s clear that advancements in resistor technology are more than just significant—they’re essential for both consumer gadgets and robust industrial systems alike!

Comparing Carbon Film, Metal Film, and Wirewound

Each type of resistor brings its own unique flair, tailored for a myriad of applications. Take carbon film resistors—these little workhorses shine in everyday use, celebrated for their budget-friendly nature and decent accuracy. Yet, they come with a temperature coefficient that can throw a wrench into performance when conditions change. Then there’s the metal film resistor, stepping up the game with enhanced precision and rock-solid stability. Thanks to their reduced noise levels and tighter tolerances, these beauties are indispensable in high-stakes electronic circuits where every detail matters.

Now let’s not forget about wirewound resistors! These heavyweights boast impressive power ratings and an uncanny ability to manage heat like champions—perfect for those situations demanding stellar thermal performance.

When it comes down to choosing among these contenders, it’s often a dance dictated by project needs. Carbon film might do just fine for your run-of-the-mill gadgets, while metal film really shines in high-performance realms. And if you find yourself wrestling with significant power demands? Wirewound resistors become your best friends—absolutely essential! Understanding these nuances helps engineers and hobbyists alike navigate the complexities of component selection deftly. Each variety offers its own set of perks along with potential pitfalls that could sway the effectiveness of electronic designs as a whole!

| Resistor Type | Advantages | Disadvantages | Ideal Applications |

|---|---|---|---|

| Carbon Film | Cost-effective, decent accuracy | Temperature coefficient can affect performance | Everyday electronics, general applications |

| Metal Film | High precision, low noise, tight tolerances | More expensive than carbon film | High-stakes electronic circuits, precision tasks |

| Wirewound | High power ratings, excellent thermal performance | Bulkier, inductance can be an issue at high frequencies | Power applications, situations with significant heat |

Trends in Resistor Design

In the ever-evolving landscape of resistor design, a whirlwind of innovation captures attention, with miniaturization and performance enhancements taking center stage. Picture this: manufacturers are diving headfirst into the realm of Surface Mount Technology (SMT), crafting diminutive components that not only shrink in size but also pack an impressive punch in terms of accuracy and efficiency. It’s a fascinating dance between tiny parts and towering expectations!

As if that weren’t enough to keep engineers on their toes, there’s a rising tide—nay, a frenzy—of demand for high-frequency applications! This surge has ignited the creation of resistors engineered to brave the storm of increased electrical stress while steadfastly preserving signal integrity like champions in the ring.

But wait! Sustainability strides onto the scene as another pivotal player. With eco-consciousness becoming more than just a buzzword, manufacturers are tapping into eco-friendly materials to lessen their environmental footprint. This strategic pivot dovetails seamlessly with broader industry movements aimed at cultivating greener electronic components—a noble quest indeed!

Designers aren’t merely content with incremental improvements; they’re unleashing waves of ingenuity through innovative processes that bolster durability yet curtail waste and energy consumption across production cycles. Imagine integrated designs where multiple functions converge within a single resistor—this visionary approach not only slashes costs but also maximizes space efficiency within circuit layouts. What an electrifying time to be part of this intricate tapestry woven from technology and sustainability!

Innovations in Color Band Technology

In the ever-evolving realm of color band technology, a whirlwind of recent breakthroughs has unfurled an array of novel materials and methodologies that dramatically amplify visibility and durability. Picture this: high-contrast, resilient inks—those vibrant warriors against fading and wear—emerging as a game-changer! This innovation guarantees that color bands retain their legibility even when battered by the elements, thereby sharpening the precision in identifying resistors. But wait, there’s more! Enter tactile features like raised dots—a clever twist offering a non-visual shortcut for swiftly deciphering resistor values. It’s a boon for all users, especially those navigating life with visual impairments.

Now let’s dive into another exciting frontier—the fusion of digital technologies within resistor manufacturing! The rise of smart resistors is upon us; these ingenious components come equipped with embedded chips that relay crucial information about specifications and conditions through wireless communication. Imagine how this leap forward not only streamlines inventory management across diverse applications but also supercharges maintenance strategies in intricate electronic systems! Such remarkable advancements encapsulate the relentless march of progress in resistor design, perfectly syncing with our growing appetite for efficiency and accessibility in every nook and cranny of electronic components.

Testing Resistors with Color Bands

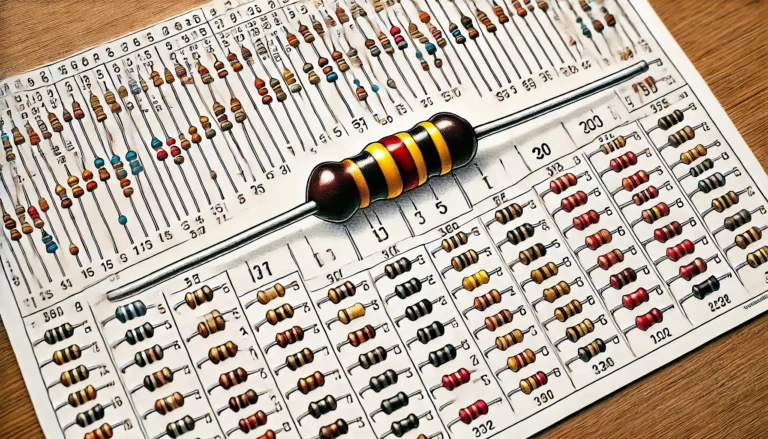

Grasping the significance of resistors through their colorful bands is no mundane task; it’s a dance of precision and verification! Each resistor boasts an array of vibrant stripes that whisper secrets about its resistance value and tolerance. To unravel these cryptic colors, one must turn to standardized charts where hues transform into numerical revelations. But beware—this isn’t just a casual glance; it demands meticulous attention! A single misstep in reading those bands could unleash chaos upon your electrical endeavors.

To elevate testing accuracy from mere guesswork to pinpoint precision, enter the multimeter—a trusty companion for every electronics enthusiast. These ingenious devices deliver direct readings of resistance, validating what those color bands claim to convey. However, don’t overlook the importance of calibration; a well-tuned multimeter is akin to having a finely sharpened tool in your kit—essential for trustworthy results! Plus, getting cozy with the unique quirks and features of different multimeters can supercharge your verification prowess. Mastering these tools not only cements theoretical insights but also hones practical expertise in the electrifying world of electronics!

Tools and Techniques for Verification

Verifying the resistance of electronic components is absolutely essential for keeping circuit integrity intact. Among the arsenal of tools at our disposal, the digital multimeter (DMM) stands out—a trusty companion that delivers precise readings by gauging voltage drop across a resistor when a known current courses through it. This method isn’t just efficient; it’s like a lightning bolt of verification, confirming color band accuracy and ensuring components live up to their specified values.

But wait! There’s more than one way to navigate this intricate maze. Enter specialized resistor color code calculators—these nifty gadgets facilitate speedy cross-referencing, especially handy when faced with an overwhelming variety of resistors or tackling environments where color perception might go awry.

Then there’s visual inspection—a cornerstone technique, particularly in classrooms buzzing with eager minds. Teaching students how to decode those colorful bands not only deepens their grasp of component specifications but also weaves in invaluable hands-on experience. Magnifying tools or even color filters can sharpen this process further, illuminating those elusive bands with clarity that would otherwise slip through the cracks.

And let’s not overlook technology! Incorporating software applications designed to recognize color codes can act as a bridge between theoretical knowledge and real-world application—an educational resource that enriches learning while nurturing meticulousness in electronic assembly and repair tasks alike. Together, these diverse tools create a symphony of learning opportunities that resonate well beyond mere circuitry!

- Digital multimeters (DMM) provide precise readings for verifying component resistance.

- Specialized resistor color code calculators streamline the process for quick reference.

- Visual inspection techniques reinforce hands-on learning for students.

- Magnifying tools enhance the visibility of resistor color bands for easier decoding.

- Software applications simplify color code recognition, bridging theory and practice.

- Combining various tools fosters a comprehensive understanding of electronic components.

- Emphasizing these techniques helps maintain circuit integrity and reliability.

The Role of Color Bands in Education

Color bands on resistors—oh, what a vibrant tapestry of knowledge they weave! These little rings of color are not just mere decorations; they’re vital educational tools that unlock the mysteries of electronics for eager minds. Each hue whispers secrets about resistor values and the very essence of resistance itself. As students embark on the journey to decode these colorful markings, they’re not just learning—they’re honing skills that are indispensable for piecing together circuits and crafting designs.

Picture this: educators diving into hands-on demonstrations where resistors come alive under scrutiny! This dynamic approach doesn’t merely teach; it sharpens problem-solving abilities and sparks critical thinking like fireworks in the night sky. Interactive sessions abound, where learners engage with real-world components, measuring and experimenting—a delightful dance between theory and practice that cements understanding deep within their minds.

As technology races forward at breakneck speed, those vibrant color bands continue to hold their ground—steadfast beacons in both academic halls and practical workshops alike. They ensure that foundational concepts in electronics remain crystal clear, lighting up pathways toward more advanced explorations yet to come.

Teaching Electronics with Practical Examples

Practical examples burst forth as a dynamic force in teaching the intricate principles of electronics, particularly when it comes to unraveling the enigma of electrical color bands. Engaging hands-on activities invite students to plunge headfirst into the world of components, merging theory with tangible reality—a fusion that ignites understanding through real-world applications. With an array of resistors at their fingertips, learners embark on a colorful journey, deciphering codes and grasping the significance each hue holds. This immersive experience doesn’t just stick; it deepens comprehension and cements knowledge about how resistors orchestrate their roles within circuits.

But wait—there’s more! Infusing simulations and project-based learning into lessons creates a rich tapestry of educational experiences. Imagine using resistor kits where color bands leap out visually; this vivid representation helps students see how these little wonders fit into larger electronic masterpieces. As they forge ahead to construct their own circuits, the act of selecting and confirming resistors based on those vibrant colors solidifies what they’ve learned. This approach not only hones technical prowess but also cultivates critical thinking skills—students become troubleshooters extraordinaire as they optimize their circuit designs, navigating challenges with creativity and insight!

Safety Considerations with Electrical Components

Electrical components, oh the peril they can unleash! One misstep in handling and the stakes skyrocket. Insulation—absolutely vital—stands as a bulwark against those pesky shocks and short circuits that lurk around every corner. Opt for components graced with stellar safety ratings; they’re your allies in the treacherous world of high-voltage scenarios, bolstering reliability like a trusty shield.

But wait, there’s more! A keen eye on wiring and connections is paramount; regular inspections can unveil lurking dangers before they spiral into chaos or calamity. Grasping the specifications and limitations of each component isn’t just advisable—it’s essential to uphold safe operational standards.

Now let’s zoom out a bit: beyond individual parts, circuit design weaves an intricate web of considerations. Adequate fusing and protective measures act as sentinels against the ominous threat of excessive current or voltage spikes. Grounding techniques? Absolutely imperative—they help curb electrical interference while safeguarding our beloved equipment from untimely demise!

And let’s not forget one crucial piece: training users on how to safely navigate this electrifying landscape cultivates an atmosphere rich in knowledge. This promotes a culture where adherence to safety protocols flourishes across diverse applications—a veritable fortress against hazards waiting to strike!

Ensuring Reliable Connections and Safety Measures

In the world of electrical applications, where currents flow and circuits hum with potential, ensuring reliable connections becomes a critical linchpin for safety and performance. The very essence of connection integrity wields tremendous power over how well a circuit operates—think about it: loose or faulty links can spiral into chaos, ushering in increased resistance, unwelcome overheating, or even catastrophic circuit failure. Thus emerges the artful dance of proper soldering techniques paired with high-quality connectors; together they stand as guardians against these lurking dangers. But wait—there’s more! Implementing strain relief measures acts as an additional layer of protection to stave off physical damage to those vital connections, boosting their durability and reliability like seasoned warriors weathering the storms of time.

Now let’s not forget that safety isn’t merely a checklist item—it encompasses choosing the right components tailored precisely for their intended purpose. Take resistors, for instance; they must be rated correctly for voltage and power to sidestep the perils of overheating. Regularly testing circuits for continuity ensures that we catch any potential hiccups before they morph into full-blown crises. And let’s talk color coding! Standardized hues on resistors serve as visual sentinels against installation errors—a simple yet effective strategy. Finally, imparting knowledge about adhering to safety protocols and sticking closely to manufacturer specifications fuels a robust culture of safety within any organization—an invisible thread binding everyone together in vigilance against electrical mishaps!

Conclusion

Grasping the intricacies of electrical color bands is absolutely crucial for anyone delving into the realm of resistors in electronics. This seemingly simple coding system allows for a rapid deciphering of resistance values—an essential skill for effective circuit design and troubleshooting endeavors. Yet, this knowledge does more than just facilitate practical applications; it deepens theoretical comprehension in educational contexts, sparking curiosity and insight.

As technology surges forward at breakneck speed, the relevance of these color bands remains undiminished. Although innovations in resistor design and manufacturing may unveil novel methods to represent values, those time-honored techniques still stand as invaluable tools—not only for novices finding their footing but also for seasoned experts honing their craft. A commitment to ongoing education about these foundational concepts will empower practitioners to uphold precision and efficiency in their work, ensuring they navigate the complexities with confidence.